Choosing the right Best OCA full lamination supplier is crucial for the success of your project. This guide provides a comprehensive overview of factors to consider when selecting a supplier, offering insights to help you make an informed decision. We'll delve into the specifics of Optical Clear Adhesive (OCA) full lamination, explore key features to look for in a supplier, and offer tips for a smooth and successful procurement process. From material quality to delivery timelines and customer support, we'll equip you with the knowledge you need to find the ideal partner for your needs.

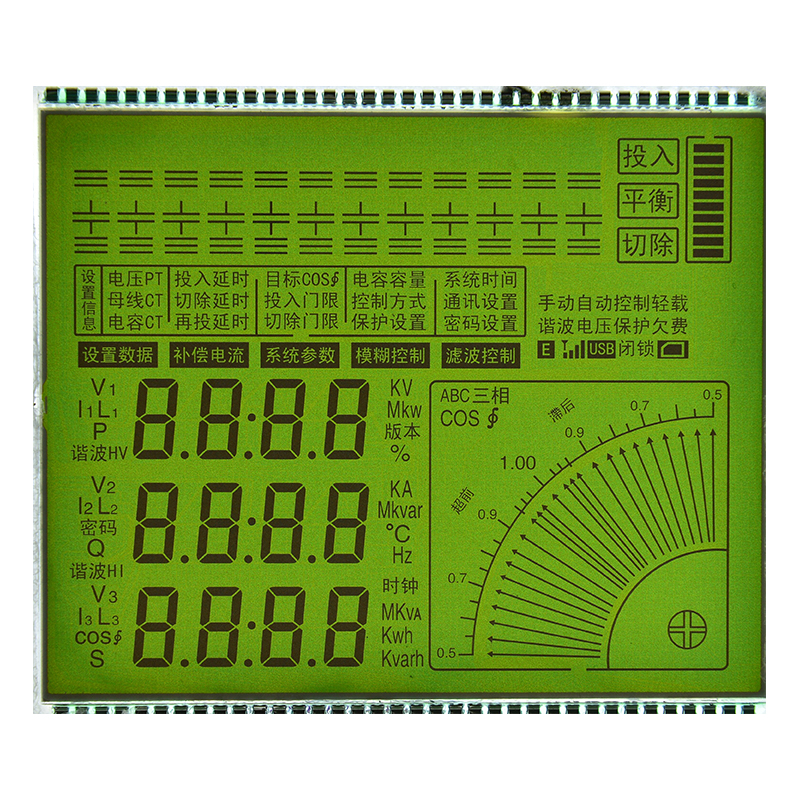

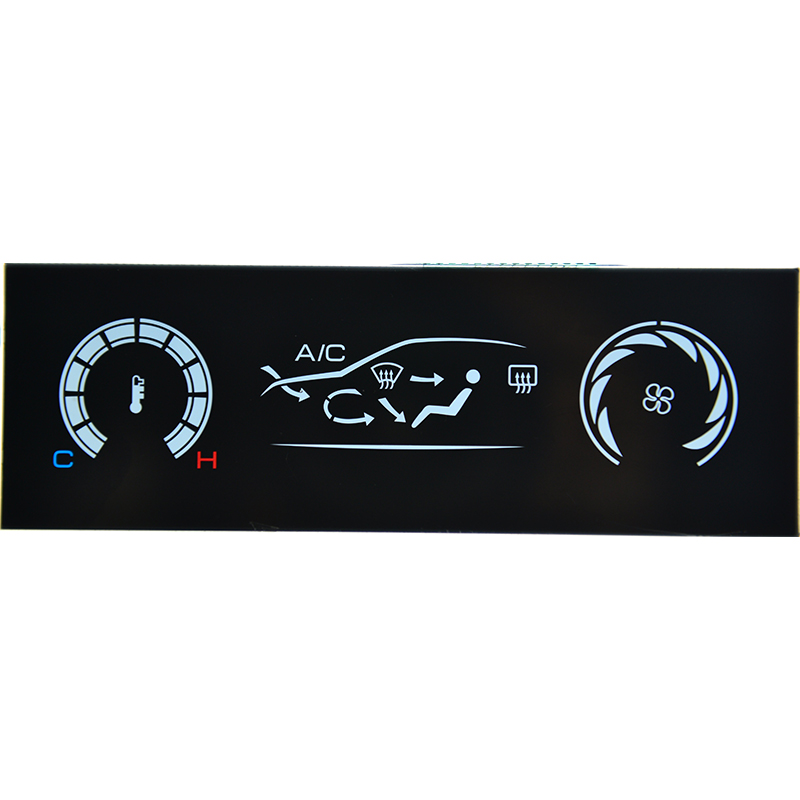

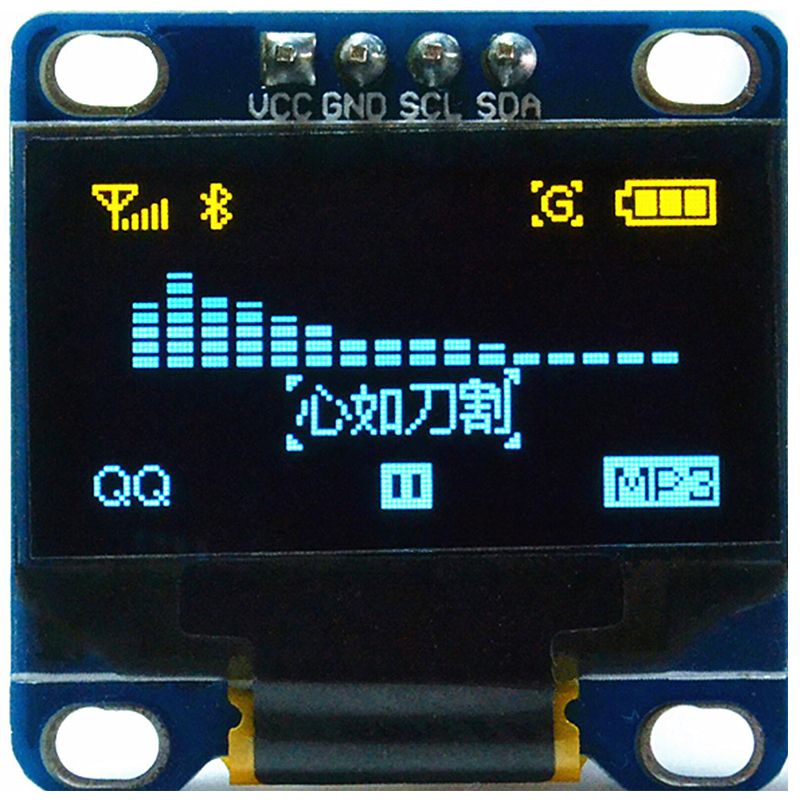

Optical Clear Adhesive (OCA) full lamination is a crucial process in the manufacturing of various displays, including smartphones, tablets, and other touch-screen devices. It involves bonding a protective layer (e.g., glass or film) to the display panel using a thin, transparent adhesive film called OCA. The result is a robust, optically clear assembly that improves durability and touch sensitivity. The quality of the OCA and the lamination process significantly impacts the final product's performance and aesthetic appeal. Selecting a reliable Best OCA full lamination supplier ensures the quality of this crucial step.

The quality of the OCA material is paramount. Look for suppliers who use high-quality OCA films with consistent optical clarity, excellent adhesion properties, and minimal air bubbles or defects. A reputable supplier will provide detailed specifications and testing results to verify the quality of their materials. Request samples to assess the quality firsthand.

Consider the supplier's production capacity to ensure they can meet your volume requirements and delivery deadlines. Inquire about their lead times and their ability to handle potential fluctuations in demand. A reliable supplier will be transparent about their production capabilities and offer realistic delivery estimates.

A skilled Best OCA full lamination supplier will provide comprehensive technical support, including assistance with material selection, process optimization, and troubleshooting. Look for suppliers with experienced engineers who can offer guidance and support throughout the project lifecycle.

Effective communication and responsive customer service are crucial. Choose a supplier that is readily available to answer your questions, address your concerns, and promptly resolve any issues that may arise. Read reviews and testimonials to gauge their customer service reputation.

Compare pricing from multiple suppliers to find a balance between cost and quality. Also, carefully review their payment terms to ensure they align with your budget and financial processes.

Researching different suppliers is vital. Consider factors like certifications (e.g., ISO 9001), customer reviews, and their overall market reputation. Many suppliers offer various OCA options; understand their specifications to ensure compatibility with your project requirements. For example, you may need OCA with specific thicknesses, optical properties, or adhesive strength depending on the application.

| Supplier | OCA Type | Lead Time | Minimum Order Quantity |

|---|---|---|---|

| Supplier A | OCA-100, OCA-200 | 2-4 weeks | 1000 units |

| Supplier B | OCA-300, OCA-400 | 3-5 weeks | 500 units |

| Dalian Eastern Display Co., Ltd. | Various, consult for specifics | Contact for quote | Contact for quote |

Selecting the Best OCA full lamination supplier requires careful consideration of numerous factors. By prioritizing material quality, production capacity, technical expertise, and customer service, you can ensure a successful partnership that contributes to the quality and efficiency of your manufacturing process. Remember to thoroughly research potential suppliers, compare their offerings, and request samples to make the best decision for your specific needs. The investment in finding the right supplier is crucial for the long-term success of your project.