This guide helps you navigate the landscape of parallel LCD factories, providing key factors to consider when selecting a supplier. We’ll cover essential aspects like production capabilities, quality control, and technological advancements, enabling you to make an informed decision that aligns with your specific needs.

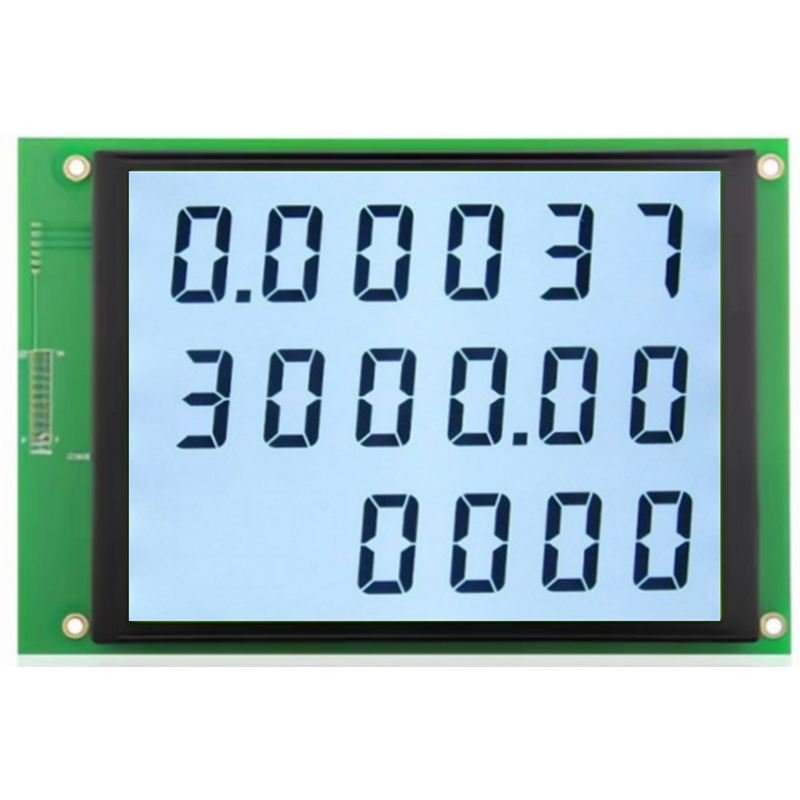

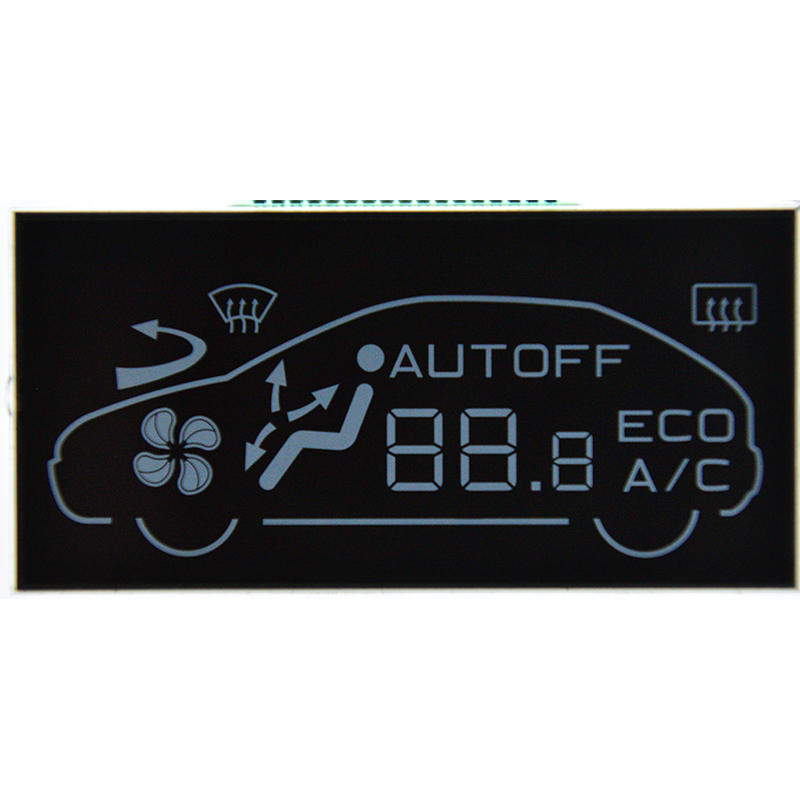

Parallel LCD technology refers to a type of Liquid Crystal Display (LCD) that uses multiple data lines to simultaneously transmit information to each pixel. This differs from serial LCDs, which transmit data sequentially. Parallel LCDs are often favored for their high speed and data transfer capabilities, making them suitable for applications requiring fast refresh rates and high resolution.

Before selecting a Best Parallel LCD factory, assess its production capacity and scalability to meet your current and future demands. Consider the factory’s manufacturing infrastructure, equipment, and workforce. A reputable factory will be transparent about its production capabilities and have a proven track record of delivering on time and within budget.

Rigorous quality control is paramount. Inquire about the factory's quality control processes, including testing procedures and defect rates. Look for factories that adhere to industry standards and have certifications like ISO 9001. High-quality components and meticulous testing ensure the reliability and longevity of the LCD panels.

The LCD industry is constantly evolving. Choose a factory that invests in research and development and keeps abreast of the latest technological advancements. This ensures access to cutting-edge technology and innovative solutions that can improve your product’s performance and competitiveness. Look for factories incorporating automation and advanced manufacturing techniques.

Does the factory offer customization options? Many applications require specific LCD panel configurations. A factory that offers flexible design and production capabilities can tailor solutions to meet precise specifications, accommodating unique requirements.

Obtain detailed pricing information and understand the payment terms. Compare quotes from multiple factories and consider the overall cost-effectiveness, factoring in production timelines and potential risks. Transparent pricing and flexible payment options indicate a reliable partner.

Consider the factory's logistics capabilities and its overall supply chain management. A reliable factory will have established processes for timely delivery and efficient handling of shipments. Inquire about their track record regarding on-time delivery and responsiveness to potential delays.

| Factory | Production Capacity | Quality Certifications | Customization Options |

|---|---|---|---|

| Factory A | High | ISO 9001, ISO 14001 | High |

| Factory B | Medium | ISO 9001 | Medium |

| Dalian Eastern Display Co., Ltd. | High | (Check their website for details) | High |

Note: This table provides a simplified comparison. Conduct thorough due diligence before making a selection.

Selecting the right Best Parallel LCD factory is crucial for success. By carefully considering the factors discussed above and conducting thorough research, you can choose a reliable partner to support your business needs. Remember to prioritize quality, technological capabilities, and a strong commitment to customer satisfaction.