This comprehensive guide helps you navigate the complexities of selecting a Best PMOLED factory, providing insights into crucial factors for making an informed decision. We explore key features, considerations, and resources to ensure you choose the right partner for your project. Learn about different manufacturing processes, quality control measures, and how to evaluate potential suppliers effectively.

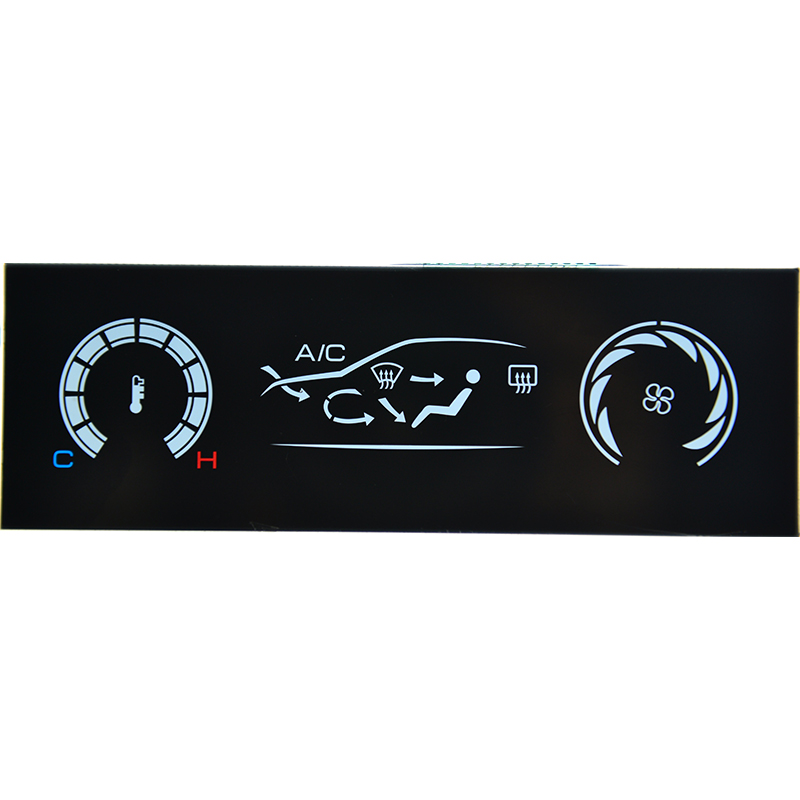

Passive-matrix organic light-emitting diodes (PMOLEDs) are a type of display technology known for their low power consumption, high contrast ratios, and excellent viewing angles. They are frequently used in applications requiring low power and high image quality, such as wearables, medical devices, and automotive displays. Understanding the nuances of PMOLED technology is crucial when choosing a manufacturer.

The versatility of PMOLED makes it suitable for a wide range of applications. From small, low-power displays in smartwatches and fitness trackers to larger displays in automotive dashboards and medical equipment, the possibilities are vast. The choice of Best PMOLED factory will depend heavily on the specific application and its requirements.

Assess the factory's production capacity to ensure they can meet your volume requirements and desired turnaround time. A factory with insufficient capacity may lead to delays in your project.

Rigorous quality control is paramount. Investigate the factory's quality assurance processes, including testing methods and defect rates. Request samples to assess the quality of their products firsthand. Look for certifications such as ISO 9001.

A leading Best PMOLED factory will constantly strive for innovation and technological advancements. Explore their research and development efforts, and inquire about their capabilities in producing customized PMOLED displays to meet your specific needs. Consider whether they offer cutting-edge technologies or are stuck with outdated methods.

Many projects require customized PMOLED displays. Evaluate the factory's ability to accommodate your specific design requirements, including size, resolution, and other features. A flexible and responsive factory can be invaluable.

Obtain detailed pricing information from several potential suppliers. Compare their quotes based on quantity, customization needs, and payment terms. Ensure transparency in their pricing structure.

Effective communication is crucial throughout the project lifecycle. Evaluate the factory's responsiveness and the quality of their customer support. A reliable partner will provide clear communication and readily address any concerns or issues that may arise.

To assist in your selection process, consider creating a comparison table for your shortlisted factories. This will help you visually compare critical factors.

| Factory | Production Capacity | Quality Control | Customization | Pricing |

|---|---|---|---|---|

| Factory A | High | Excellent | High | Competitive |

| Factory B | Medium | Good | Medium | Moderate |

| Factory C | Low | Fair | Low | Budget-friendly |

Remember to replace the placeholder data with your own research.

Online resources, industry directories, and trade shows can help you identify potential Best PMOLED factory candidates. Always conduct thorough due diligence, including site visits if possible, to validate their claims and assess their capabilities firsthand. Don't hesitate to ask for references and check reviews from previous clients.

For a reliable and high-quality Best PMOLED factory option, consider exploring Dalian Eastern Display Co., Ltd.. They offer a wide range of display solutions.

Choosing the right Best PMOLED factory is a critical decision. By carefully considering the factors outlined in this guide and performing thorough research, you can select a partner that will meet your needs and contribute to the success of your project.