Discover the top manufacturing facilities responsible for producing Samsung's renowned OLED displays. This comprehensive guide delves into the technology, processes, and key considerations involved in creating these high-quality screens, examining factors that contribute to a factory's excellence in producing Best samsung oled display factory products. Learn about the intricate details behind the production, from materials sourcing to quality control.

Samsung's OLED displays utilize organic light-emitting diodes, offering superior picture quality with deep blacks, vibrant colors, and wide viewing angles. This technology sets them apart from other display types, making them a popular choice for high-end televisions, smartphones, and other devices. The manufacturing process is intricate and requires specialized facilities and equipment. The pursuit of the Best samsung oled display factory is a constant drive for innovation and efficiency.

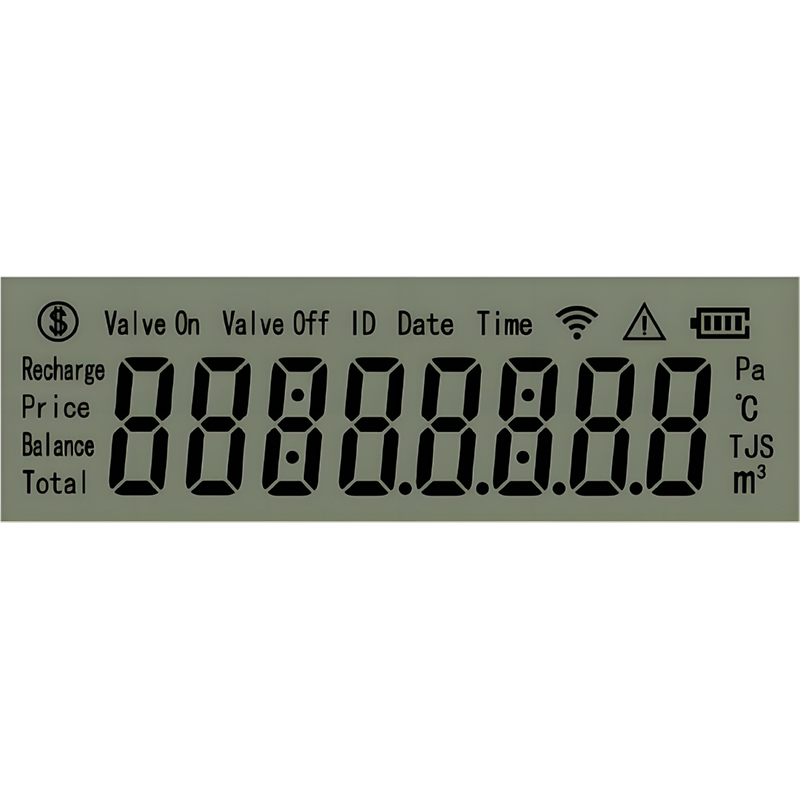

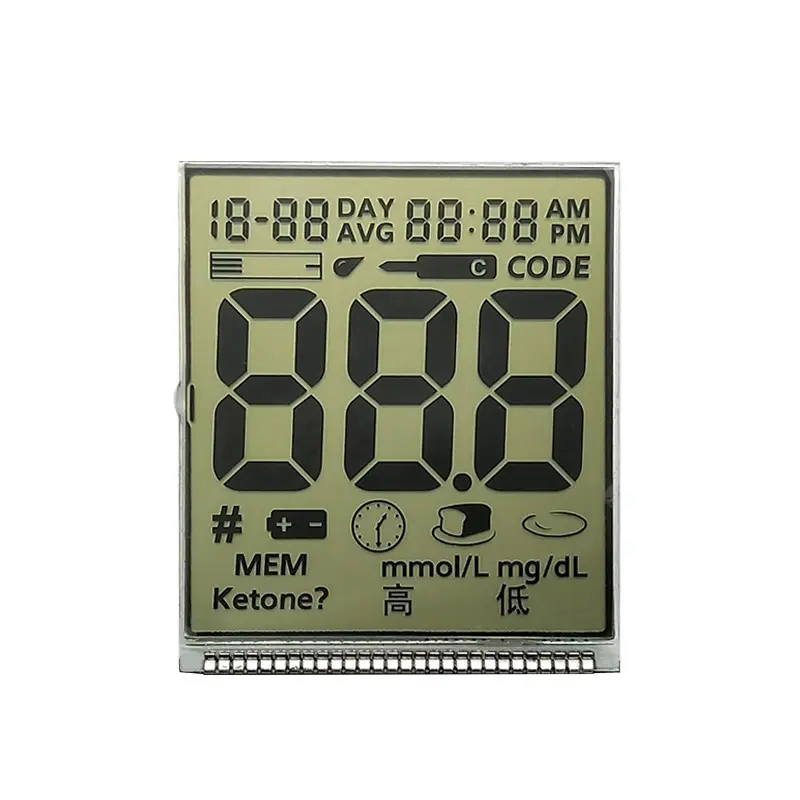

A top-tier Best samsung oled display factory necessitates a blend of advanced technology, skilled labor, and rigorous quality control measures. Key aspects include state-of-the-art equipment for precise deposition of organic materials, sophisticated cleanroom environments to minimize contamination, and advanced inspection systems for ensuring consistent quality across production runs. Effective supply chain management is also critical for sourcing high-quality materials.

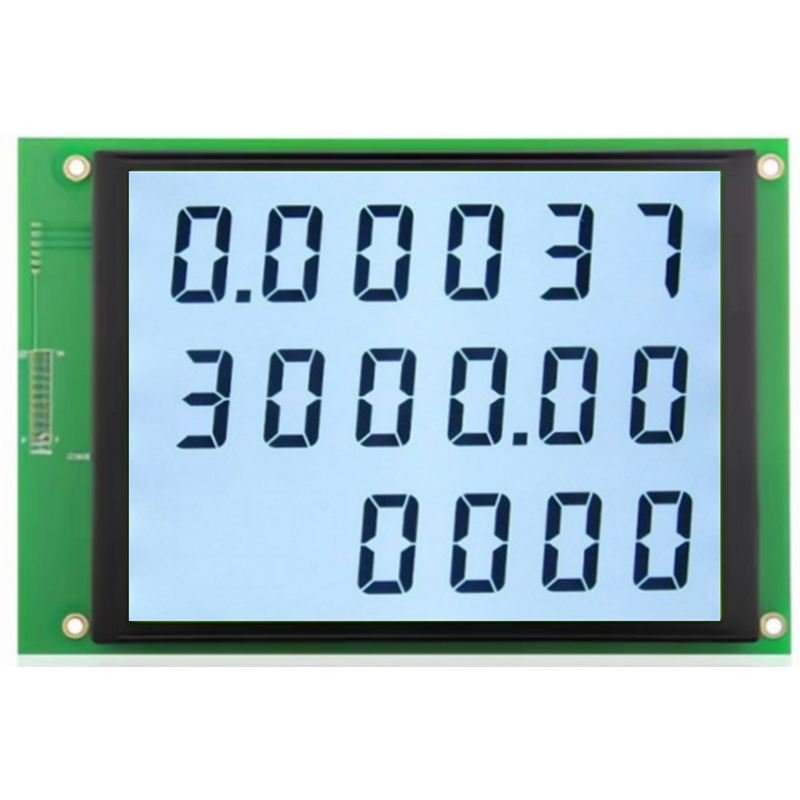

The capacity of a factory to produce OLED displays efficiently is a key indicator of its effectiveness. This includes the speed of the production line, minimizing waste, and optimizing resource utilization. High-volume production, while maintaining quality standards, is a hallmark of leading Best samsung oled display factory facilities.

Maintaining a low defect rate is crucial for any OLED display factory. Rigorous quality control processes, including in-line and final inspections, are essential to ensure that only high-quality displays leave the factory. This commitment to excellence is fundamental in the search for the Best samsung oled display factory.

The pursuit of the Best samsung oled display factory necessitates continuous innovation. Factories that invest in research and development, adopt the latest technologies, and embrace process improvements tend to outperform their competitors. This constant drive for improvement ensures that they are at the forefront of OLED display manufacturing.

Modern Best samsung oled display factory operations increasingly prioritize environmentally responsible practices. Minimizing waste, reducing energy consumption, and employing sustainable materials are gaining significant importance in the industry. This reflects a broader commitment to corporate social responsibility.

While specific factory locations aren't publicly disclosed by Samsung for competitive reasons, it's understood that multiple facilities across different regions contribute to their global OLED production. The focus remains on maintaining consistent quality standards across all production sites. The ultimate goal is to consistently deliver the Best samsung oled display factory output, regardless of geographical location.

For further information on advanced display technologies and manufacturing capabilities, you might find information on related companies like Dalian Eastern Display Co., Ltd. helpful. They offer insights into the broader display manufacturing landscape.

The quest for the Best samsung oled display factory is an ongoing process driven by technological advancements, stringent quality control, and a commitment to operational efficiency. By considering factors like production capacity, defect rates, technological innovation, and environmental responsibility, we can better appreciate the complexities and dedication involved in creating these remarkable displays.