This guide explores effective methods for managing the power-down and data communication termination of serial-interfaced TFT displays, ensuring data integrity and preventing hardware damage. We'll cover best practices, common pitfalls, and practical solutions for various scenarios.

Improperly powering down a serial TFT display can lead to data corruption or even permanent hardware failure. Always adhere to the manufacturer's specified power-down sequence. This often involves a specific sequence of commands or a timed process to allow the display controller to safely enter a low-power state. Ignoring this can result in screen glitches, data loss, and ultimately, the need for a costly replacement. Check your specific display's datasheet for the recommended procedure. Failing to do so may result in unexpected behavior.

Terminating serial communication with a serial TFT display requires attention to detail. Abruptly cutting the connection can leave the display in an undefined state. The best practice is to send a specific command signaling the end of the data transmission before powering down the display. This allows the display controller to properly process the received data and transition to a safe state. Many controllers have built-in mechanisms to handle such graceful shutdowns; consult your display's documentation to understand the appropriate commands. For instance, some displays require a specific sleep command before power is removed.

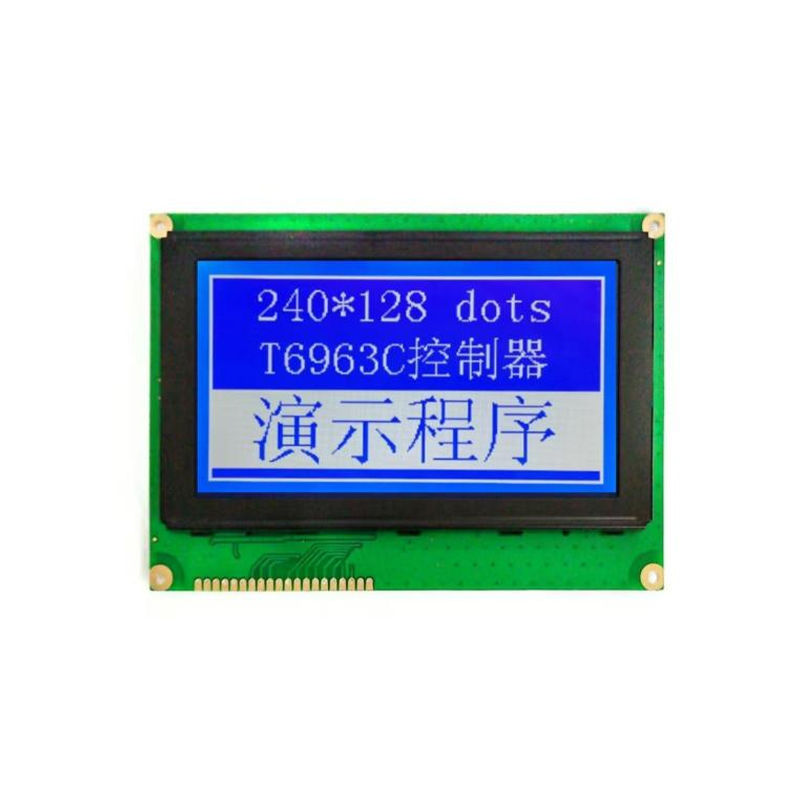

The choice of serial interface (e.g., SPI, I2C, parallel) impacts the complexity of the serial TFT display exit strategy. SPI and I2C interfaces typically require less complex communication protocols, simplifying the shutdown process. However, parallel interfaces, while offering higher data throughput, can require more rigorous power-down procedures to avoid data corruption.

If you're experiencing display glitches after powering down your serial TFT display, it's crucial to revisit the power-down sequence and check for any discrepancies with the manufacturer's specifications. Double-check the timing of the signals and ensure that all necessary commands are sent before power is removed. Sometimes, a simple capacitor addition can also improve the power-down stability.

Data corruption suggests a problem with the serial communication protocol or the hardware itself. Ensure that your communication lines are correctly wired and that the baud rate, data bits, parity, and stop bits are correctly configured. Using a logic analyzer can be incredibly helpful in diagnosing these kinds of issues. Addressing these issues proactively minimizes the chances of requiring a serial TFT display replacement.

Many modern serial TFT displays allow for firmware updates that enhance power management features. These updates often include optimized power-down routines and improved handling of unexpected power loss. Checking for firmware updates is a crucial step in optimizing the performance and longevity of your display. This process often involves specialized software and careful adherence to the manufacturer's instructions.

In some cases, minor hardware modifications, such as adding decoupling capacitors or using a more robust power supply, can significantly improve the reliability of the serial TFT display and its power management. Consult with a qualified electronics engineer to assess the feasibility of such modifications for your specific application. Improper modifications can void warranties and potentially damage the display.

For more detailed information on specific serial TFT display models and their power management requirements, please refer to the manufacturer's datasheets and documentation. Many manufacturers offer extensive online resources and technical support to help you troubleshoot issues and optimize performance. Consider contacting Dalian Eastern Display Co., Ltd. for high-quality TFT displays and expert support. Their expertise in the field can be invaluable when dealing with complex power management scenarios.

| Interface | Advantages | Disadvantages |

|---|---|---|

| SPI | Simple, relatively fast | Can be more complex to implement for larger displays |

| I2C | Easy to implement, fewer pins | Slower data transfer rates than SPI |

| Parallel | High data transfer rates | Requires more pins, complex power-down procedures |