Best SPI Interface with Microcontroller FactoryThis article provides a comprehensive guide to selecting the best SPI interface for your microcontroller project, focusing on factors to consider when choosing a Best spi interface with microcontroller factory and highlighting key aspects for successful integration. We'll explore different SPI interface options, their strengths and weaknesses, and offer practical advice for seamless implementation. The information presented is tailored for engineers and developers seeking to optimize their microcontroller projects.

Understanding SPI Communication

What is SPI?

SPI (Serial Peripheral Interface) is a synchronous, full-duplex communication bus commonly used to connect microcontrollers to various peripherals like sensors, ADCs, DACs, and memory chips. Its popularity stems from its relatively simple hardware implementation, high speed, and versatile features. The interface involves a master device (typically a microcontroller) and one or more slave devices. Data transfer occurs simultaneously in both directions.

Key SPI Interface Features

Simplicity: SPI's straightforward protocol makes it easy to implement and use. Speed: It supports high data transfer rates, ideal for time-sensitive applications. Full-Duplex: Simultaneous data transmission and reception improve efficiency. Multi-Master Capability: While less common, some SPI implementations allow multiple master devices. Flexibility: SPI can be adapted to various communication speeds and data formats.

Choosing the Right SPI Interface for Your Microcontroller

Selecting the optimal

Best spi interface with microcontroller factory depends heavily on your specific needs. Consider these factors:

Data Rate Requirements

The required data transfer speed dictates the SPI clock frequency. Higher speeds demand faster microcontrollers and peripherals capable of handling the increased data throughput.

Number of Peripherals

SPI can handle multiple slave devices through chip select (CS) lines. However, you must consider the available CS lines on your microcontroller and the complexity of managing multiple slaves.

Distance Between Devices

For longer distances, signal integrity becomes crucial. This might necessitate using differential signaling or level shifting techniques.

Power Consumption

SPI's power consumption is generally low, but this can still be a concern for battery-powered applications. Optimize your system for low-power operation where necessary.

SPI Interface Considerations with Different Microcontrollers

Different microcontrollers offer varying SPI implementations. Some key aspects to consider:

Peripheral Support

Ensure your chosen microcontroller has enough SPI modules to accommodate all your peripherals.

Interrupt Handling

Efficient interrupt handling is critical for real-time applications.

DMA Capabilities

Direct Memory Access (DMA) can significantly offload the CPU, freeing resources for other tasks and potentially improving data transfer speeds.

Finding the Right Best spi interface with microcontroller factory

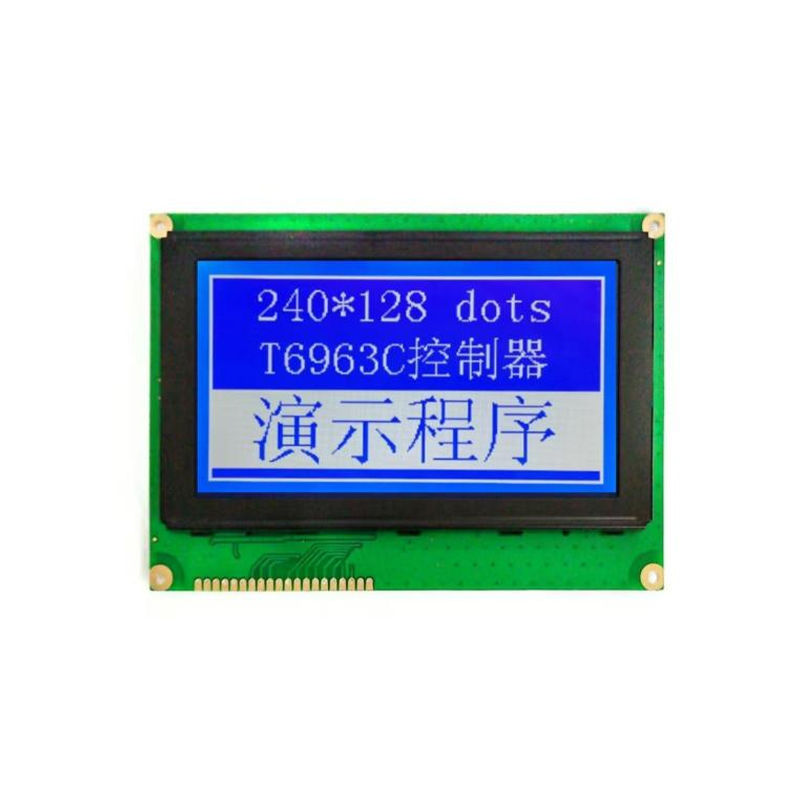

Sourcing reliable components is vital for a successful project. Consider factors like component quality, lead times, and technical support when selecting a supplier. Many reputable distributors offer a wide range of microcontrollers with various SPI interfaces. For high-quality LCD displays suitable for integration with your SPI-based microcontroller systems, consider exploring options from Dalian Eastern Display Co., Ltd. They provide a variety of display solutions and technical expertise. You can learn more by visiting their website:

https://www.ed-lcd.com/Troubleshooting Common SPI Issues

Debugging SPI communication problems can be challenging. Common issues include incorrect clock polarity/phase settings, wiring errors, and timing violations. Thorough testing and careful verification are essential.

Conclusion

Choosing the right SPI interface for your microcontroller project requires careful consideration of multiple factors. By understanding the nuances of SPI communication and carefully evaluating your specific needs, you can select the optimal

Best spi interface with microcontroller factory for your application, ensuring efficient and reliable data transfer. Remember to always refer to the datasheets of your chosen microcontrollers and peripherals for detailed specifications and implementation guidance.

| Feature | SPI | I2C |

| Data Rate | Higher | Lower |

| Complexity | Simpler | More Complex |

| Wiring | More Wires | Fewer Wires |