This guide explores the best LCD monitor testing methods to ensure quality control and efficient exit strategies for your manufacturing process or repair workflow. We'll cover various testing procedures, equipment, and considerations to minimize defects and maximize productivity. Choosing the right best test monitor lcd exit strategy is crucial for any business dealing with LCD displays.

Rigorous testing of LCD monitors is paramount to maintaining high product quality, reducing returns, and boosting customer satisfaction. Defective displays can lead to significant losses, impacting brand reputation and profitability. A well-defined best test monitor lcd exit process minimizes these risks.

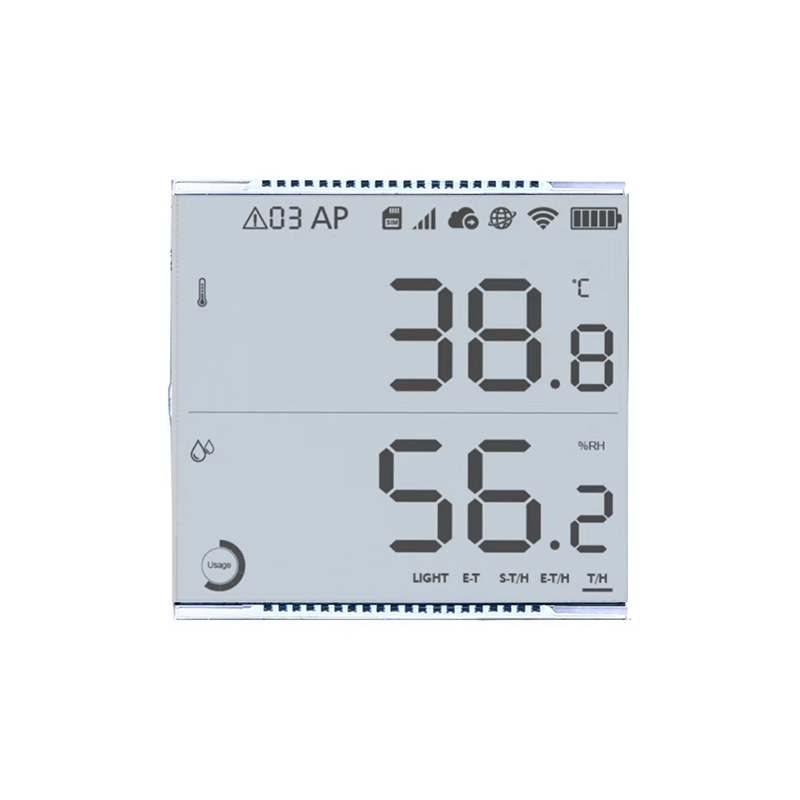

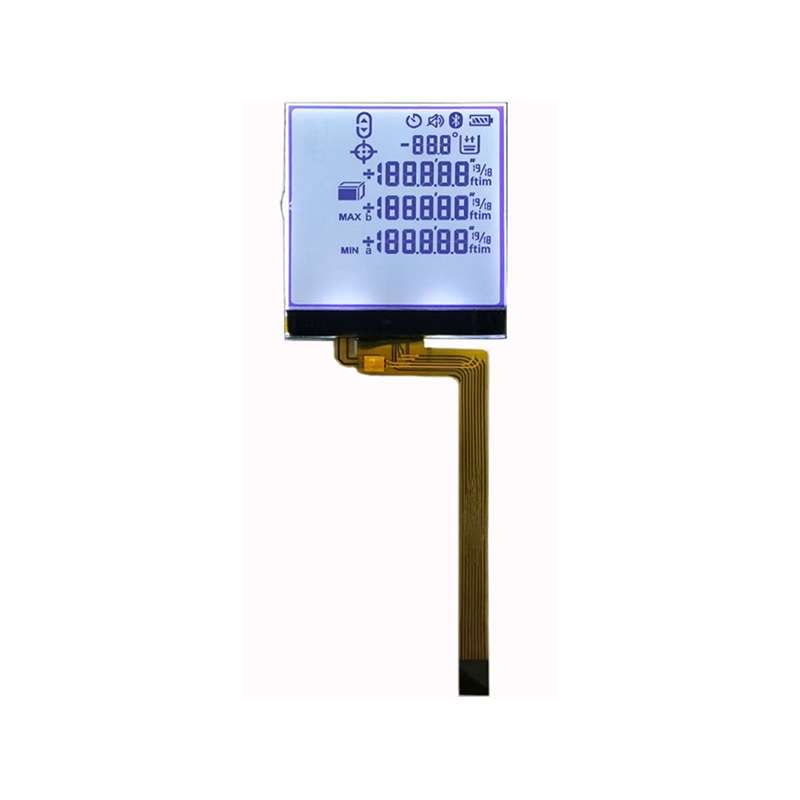

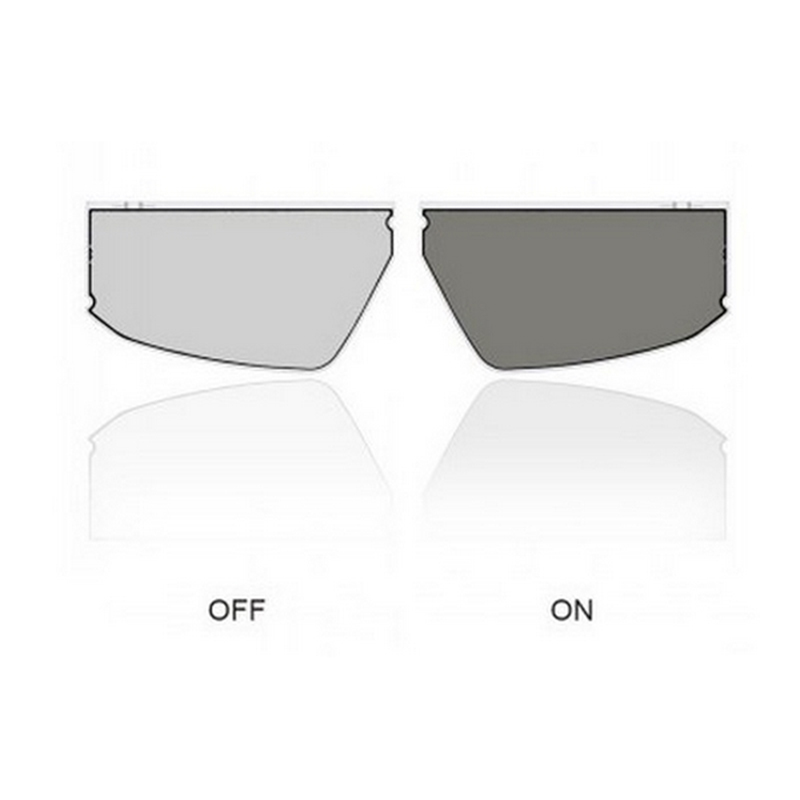

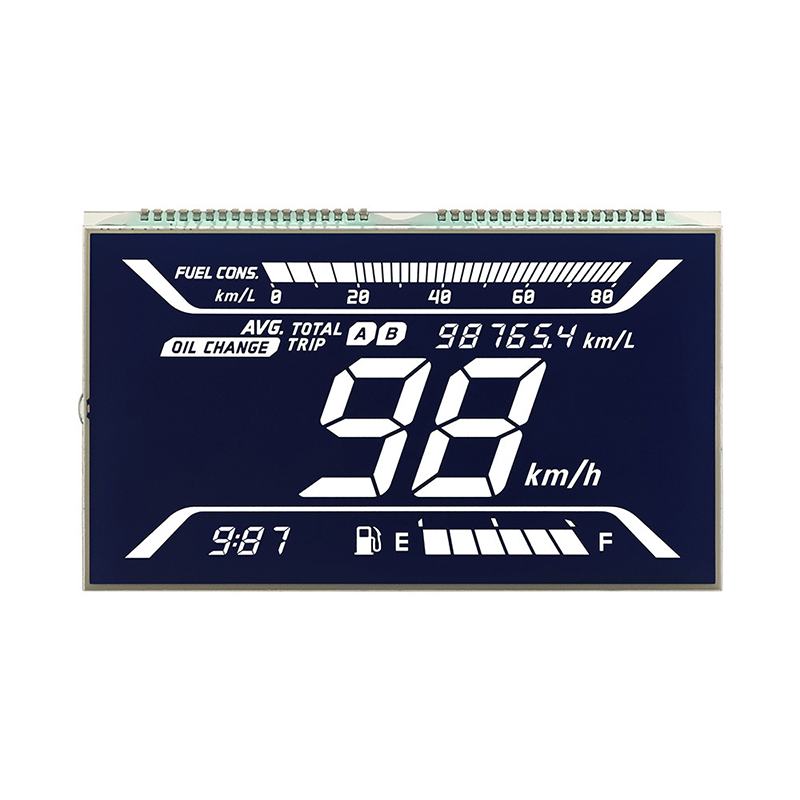

Potential defects include dead pixels, backlight issues, color inaccuracies, screen flickering, and image distortions. Effective testing must identify these issues before the monitor leaves the production line or repair facility. Different testing methodologies cater to various defect types.

A basic but crucial first step involves a thorough visual inspection for obvious defects like scratches, cracks, or physical damage. This initial check helps to quickly identify easily visible issues, reducing the load on more advanced testing methods.

Automated testing systems offer efficiency and consistency. These systems can perform a range of tests, including backlight uniformity checks, color accuracy measurements, and pixel response time evaluations. Investing in high-quality automated equipment is a key element of a robust best test monitor lcd exit strategy. Several reputable manufacturers offer such equipment; research is key to selecting the best fit for your needs and budget. For detailed specifications, check out manufacturers' websites.

Software solutions allow for comprehensive testing of various aspects, such as color accuracy, response time, and image quality. These tools often provide detailed reports, facilitating data analysis and quality control monitoring. Many free and paid software options are available, each with its own strengths and weaknesses.

Before implementing a best test monitor lcd exit strategy, establish clear acceptance criteria. This involves defining acceptable levels for various parameters, such as the maximum number of acceptable dead pixels or the acceptable range of color accuracy deviation. These criteria should align with industry standards and your specific product requirements.

A strong quality assurance (QA) process is vital. This involves regular calibration of testing equipment, consistent application of testing procedures, and meticulous documentation of testing results. A well-defined QA process ensures the reliability and accuracy of your testing methodology and directly impacts your best test monitor lcd exit process.

For large-scale operations, comprehensive data analysis is essential. This enables you to identify trends, pinpoint recurring issues, and make informed decisions regarding process improvements and resource allocation. Analyzing test results can reveal patterns indicating underlying manufacturing or component problems.

Integrating your testing processes with existing inventory management and production systems streamlines your workflow. Automated data transfer between systems minimizes manual data entry and reduces the risk of errors. A seamless data flow is crucial for efficient operation.

Developing a reliable and efficient best test monitor lcd exit process requires careful planning and the implementation of appropriate testing methods. By combining visual inspection, automated testing equipment, and software-based solutions, manufacturers and repair facilities can significantly improve product quality, minimize waste, and maximize customer satisfaction. Remember that consistent QA processes and data analysis are critical for long-term success. Consider contacting a provider like Dalian Eastern Display Co., Ltd. for high-quality LCD displays and components.