This guide helps you navigate the market for Best Tester LCD suppliers, providing crucial insights to make an informed decision. We'll cover key factors to consider when selecting a supplier, including product quality, testing capabilities, and overall reliability. Learn how to evaluate potential suppliers and find the perfect partner for your LCD testing needs.

Before searching for a Best Tester LCD supplier, clearly define your specific requirements. Consider the types of LCDs you'll be testing (e.g., size, resolution, technology), the testing parameters (e.g., brightness, contrast, response time), and the volume of testing you anticipate. Understanding these factors will help you narrow down your options and find a supplier that perfectly aligns with your needs.

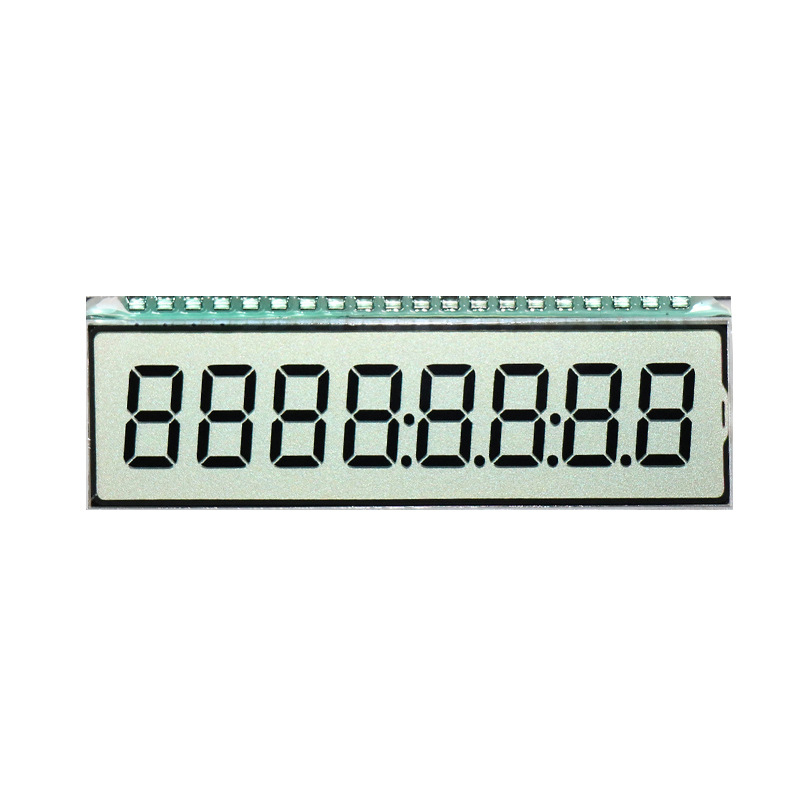

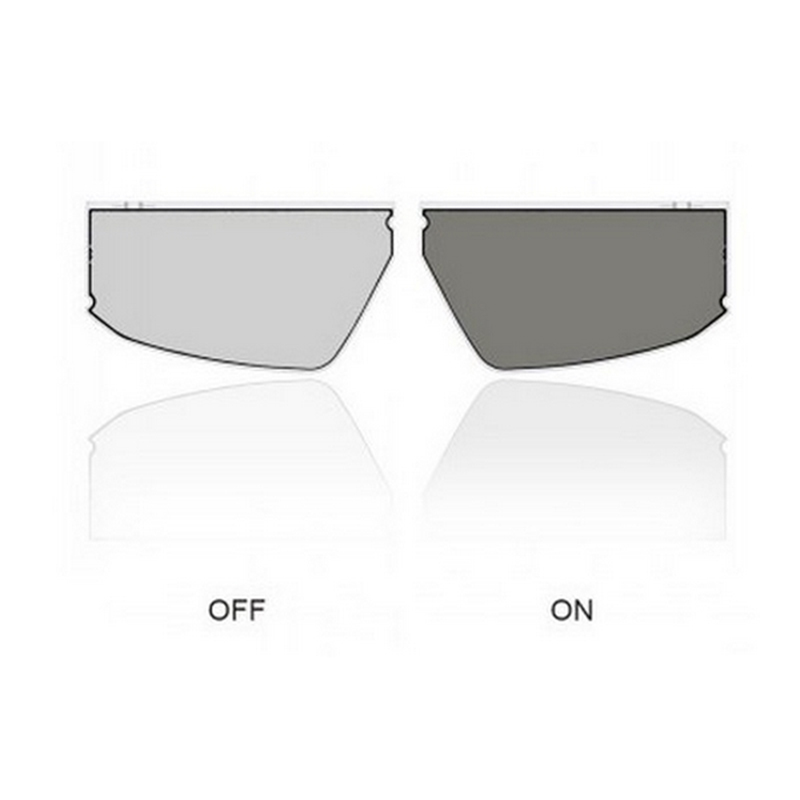

Various testing methods exist, including functional testing, visual inspection, and electrical testing. Some Best Tester LCD suppliers specialize in certain types of testing, so identifying your priorities is crucial. For instance, you might need a supplier proficient in automated optical inspection (AOI) for high-volume production or a supplier specializing in burn-in tests for durability assessment. A reputable supplier will clearly outline their testing capabilities and certifications.

A reliable Best Tester LCD supplier provides high-quality LCDs and consistent performance. Look for suppliers with a proven track record, positive customer reviews, and certifications like ISO 9001. Request samples to assess the quality firsthand and examine the supplier's testing methodologies to verify their commitment to quality control.

The supplier's testing capabilities should align with your needs. Advanced testing equipment and experienced technicians are vital for accurate and reliable results. Investigate the supplier's use of automated testing systems and their ability to handle different LCD types and sizes. Consider whether they offer customized testing solutions tailored to your specific requirements.

Thoroughly research potential suppliers. Check online reviews, industry forums, and seek references from other companies. A reputable supplier will be transparent about their processes, provide excellent customer support, and have a clear return policy. Consider factors such as response time, communication effectiveness, and the availability of technical assistance. A strong relationship with your supplier is essential for long-term success.

Clearly articulate your LCD testing requirements, including the types of LCDs, testing parameters, and testing volume.

Use online resources and industry directories to identify potential Best Tester LCD suppliers. Check their websites, certifications, and online reviews.

Contact potential suppliers to request quotes and samples. Compare pricing, lead times, and the quality of the samples.

Verify the supplier's credentials, reputation, and capabilities. Check for certifications and references.

Choose the supplier that best meets your needs in terms of quality, price, reliability, and support.

| Factor | Importance | How to Evaluate |

|---|---|---|

| Quality Control | High | Check certifications (e.g., ISO 9001), request samples, and review customer feedback. |

| Testing Capabilities | High | Review the supplier's equipment list, expertise, and ability to handle your specific LCD types. |

| Pricing and Lead Times | Medium | Request quotes from multiple suppliers and compare pricing and delivery schedules. |

| Customer Support | Medium | Check online reviews and contact the supplier directly to assess their responsiveness and helpfulness. |

Finding the right Best Tester LCD supplier is a crucial decision. By carefully considering the factors outlined in this guide, you can ensure you select a partner that delivers high-quality products, reliable testing services, and excellent support. For high-quality LCDs and related services, consider exploring options like Dalian Eastern Display Co., Ltd. Remember to always conduct thorough research and due diligence before making your final decision.