Choosing the right exit strategy for your TFT display module is crucial for preserving its lifespan and ensuring the safety of your device. This comprehensive guide covers various methods for disconnecting and disposing of these modules, tailored to different types and scenarios. We’ll focus on best practices to avoid common pitfalls and maximize the longevity of your system. Consider factors like the type of module, its connection method, and the intended use of the display. The information provided here is applicable for engineers, technicians, and anyone working with TFT display modules.

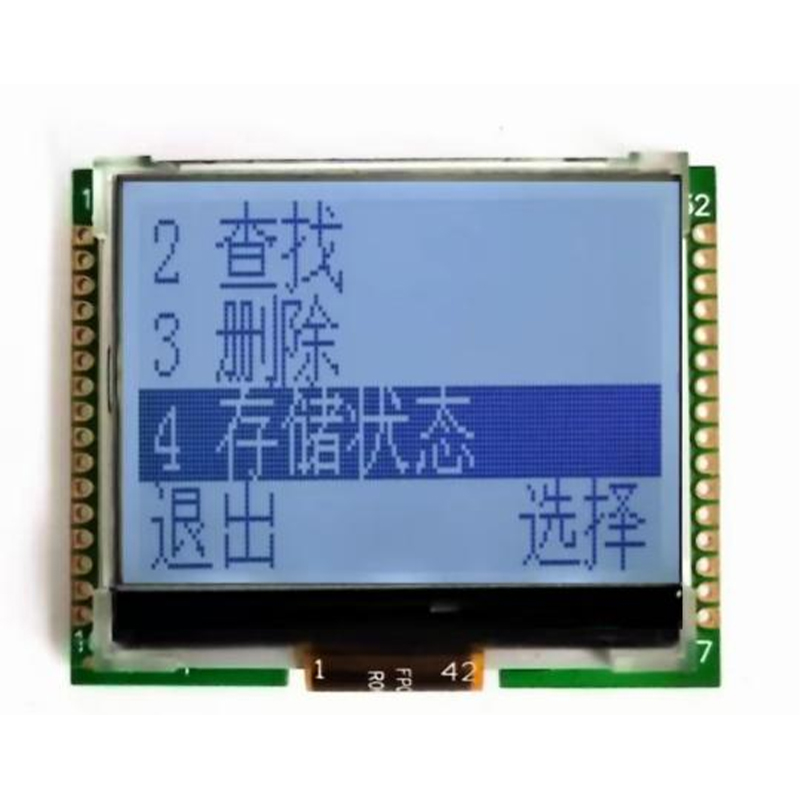

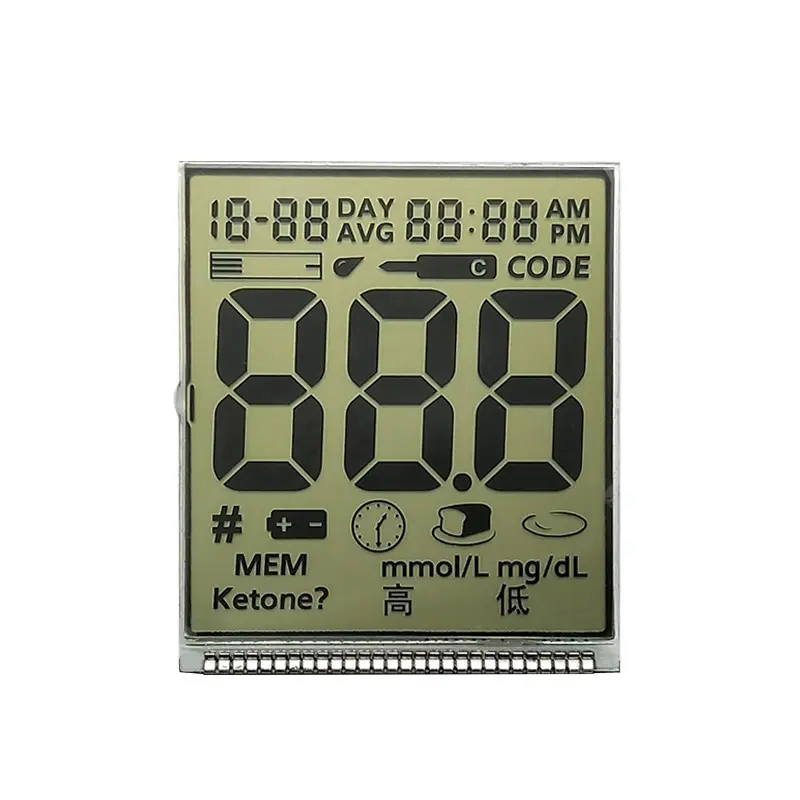

Before discussing exit strategies, it’s crucial to understand the variations in TFT display modules. These modules differ based on their size, resolution, interface type (e.g., LVDS, MIPI, TTL), and power requirements. The connection method, whether it involves a ribbon cable, a connector, or direct soldering, significantly impacts the disconnection procedure. Incorrect handling can lead to damage, so understanding your specific module is the first step.

Carefully examine your TFT display module for markings indicating its manufacturer, model number, and specifications. These details will help you find the proper disconnection procedure in the module's datasheet. Datasheets often provide crucial information on power sequencing and signal handling during shutdown. If you can't locate the datasheet, refer to the module's manufacturer's website. Many manufacturers like Dalian Eastern Display Co., Ltd. provide comprehensive technical documentation.

Proper disconnection of a TFT display module prevents data corruption, physical damage to the module and connecting device, and protects the longevity of your device. The process depends largely on the interface and connection type.

When dealing with ribbon cable connections, always use the latch mechanism or connector provided. Never pull on the cable itself. Gently unlatch the connector, ensuring a secure and straight pull to avoid bending or damaging the pins. Always power down the system completely before disconnecting any ribbon cables.

For connector-based connections, ensure the system is powered off before attempting to disconnect the module. Use appropriate tools to safely disconnect the connectors, avoiding unnecessary force.

Disconnecting directly soldered TFT display modules requires specialized tools and expertise. This is generally not a DIY task and should only be performed by qualified professionals. Incorrect desoldering can permanently damage the module or the main board.

Once the TFT display module is removed, proper disposal is paramount. Many TFT display modules contain materials that can harm the environment if disposed of improperly. Check for local regulations on electronic waste recycling. Many recycling centers accept electronic components, and some manufacturers may have specific take-back programs.

During the disconnection or disposal process, you might encounter certain issues. This section addresses some of the most common challenges and provides solutions.

If the module doesn’t power off even after the system shutdown, check the power supply and ensure the correct power sequencing is followed. Consult the module's datasheet for detailed instructions on power management.

If the connectors or cables are damaged, replacing them is crucial. Using damaged components can lead to further issues and even damage other system components. Always ensure you use quality replacement parts that are compatible with your TFT display module.

Successfully exiting a TFT display module requires careful planning and execution. Understanding your module's type, interface, and connection method is paramount for a safe and efficient process. Following the steps outlined above, combined with consulting the module's datasheet, significantly minimizes the risk of damage and extends the operational lifespan of your device. Remember to prioritize safe disposal practices to protect the environment.