Choosing the right TFT screen for a car factory demands careful consideration of several critical factors. This guide explores key aspects to help you select the optimal display solution for your specific needs, ensuring efficiency, durability, and seamless integration into your manufacturing processes. We'll examine different screen types, resolutions, brightness levels, and other essential features, providing you with a comprehensive understanding to make an informed decision.

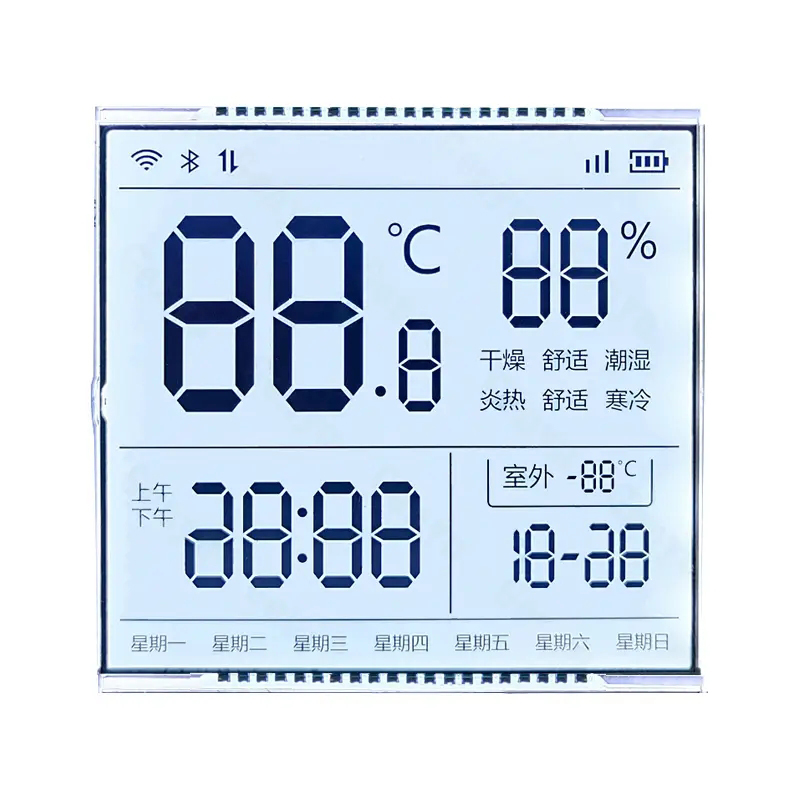

Car factories present a challenging environment for electronic displays. They often endure exposure to dust, debris, oil, and extreme temperatures. Therefore, selecting a best TFT screen for car factory requires prioritizing durability. Look for screens with robust housings, protective coatings, and high impact resistance. Consider screens with an IP rating (Ingress Protection rating) indicating their resistance to dust and water ingress. A higher IP rating signifies greater protection against environmental factors.

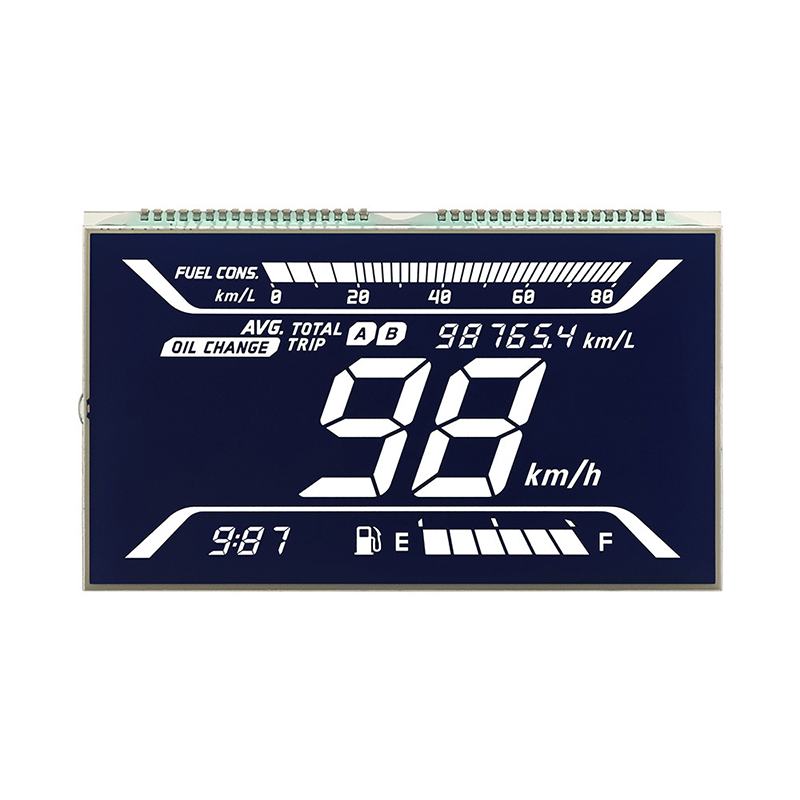

In brightly lit factory settings, screen readability is crucial. The best TFT screen for car factory will boast high brightness levels (measured in nits) to ensure clear visibility even under direct sunlight or strong artificial lighting. Consider screens with anti-glare coatings to minimize reflections and improve readability further.

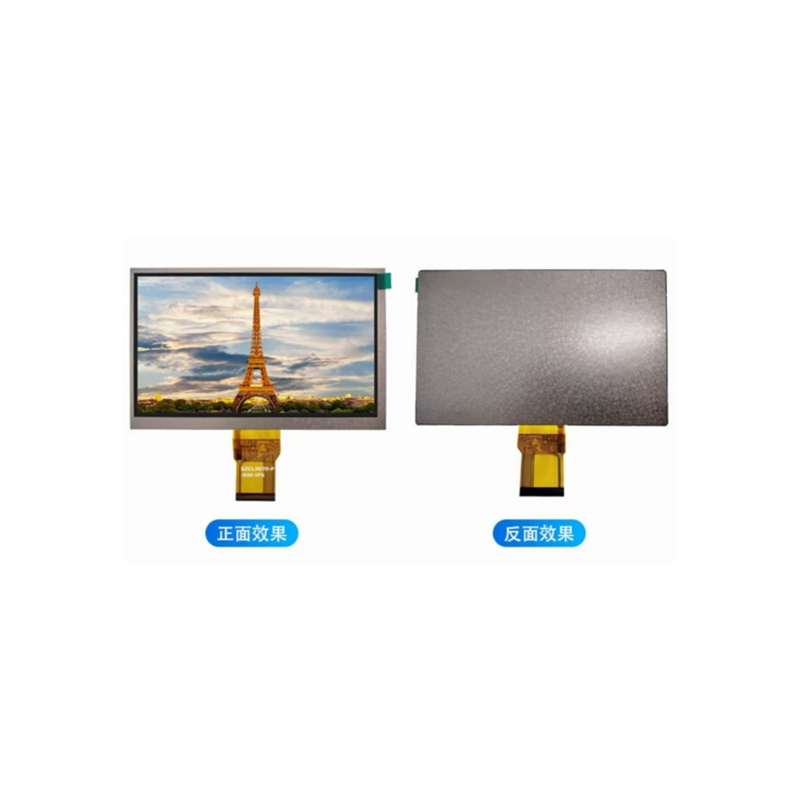

The required resolution and screen size depend on the specific application. For monitoring production lines, a large screen with a high resolution might be necessary to display detailed information clearly. For smaller control panels, a compact screen with sufficient resolution would suffice. Assess your application's requirements to determine the appropriate screen size and resolution for optimal performance.

The chosen best TFT screen for car factory should seamlessly integrate with existing factory systems. Consider connectivity options such as HDMI, VGA, DVI, or DisplayPort, depending on your equipment's compatibility. Some industrial TFT screens offer specialized communication protocols for seamless integration with industrial automation systems.

Designed specifically for demanding industrial environments, these screens offer superior durability, reliability, and extended lifespan compared to consumer-grade displays. They typically feature enhanced resistance to shock, vibration, and temperature fluctuations. Many industrial TFT screens also offer extended temperature operating ranges, making them suitable for diverse factory environments.

Ruggedized TFT screens are engineered to withstand harsh conditions, often featuring sealed construction, reinforced housings, and protective coatings. They are ideal for applications where the display is subjected to impacts, vibrations, or extreme temperatures. Their robust design ensures reliable operation in demanding industrial settings.

The following table summarizes key features to consider when selecting a best TFT screen for car factory:

| Feature | Considerations |

|---|---|

| Resolution | Higher resolution for detailed viewing; consider the viewing distance. |

| Brightness (nits) | Higher brightness for visibility in bright environments. Aim for at least 700 nits for most factory applications. |

| IP Rating | Higher IP rating indicates better protection against dust and water. |

| Connectivity | Choose appropriate interfaces (HDMI, VGA, etc.) based on your existing systems. |

| Operating Temperature Range | Ensure the screen can withstand the temperature fluctuations in your factory. |

Several reputable suppliers offer high-quality best TFT screen for car factory solutions. For specific product recommendations and detailed specifications, it's best to contact suppliers directly. Remember to always check reviews and compare specifications before making a purchase. Consider contacting Dalian Eastern Display Co., Ltd. for their range of industrial displays, which could be a suitable option for your needs.

Remember that this is a general guide, and the ideal best TFT screen for car factory will depend heavily on your specific requirements. Careful consideration of these factors is crucial for a successful selection. Consult with industry experts if needed to ensure you choose the best option for your specific application.