This comprehensive guide helps you navigate the landscape of Best Wearable OLED factory options, considering factors like production capacity, technology expertise, and quality control. We explore key considerations to help you make an informed decision for your wearable device project.

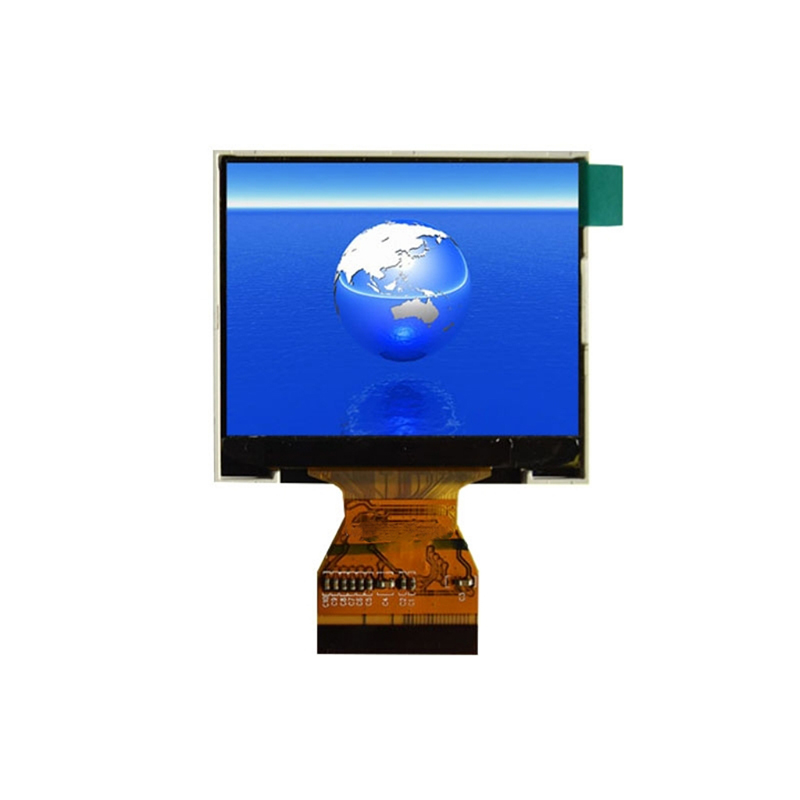

OLED (Organic Light-Emitting Diode) technology offers several key advantages for wearable displays. Its flexibility, low power consumption, and vibrant color reproduction make it ideal for smaller, more power-sensitive devices. Compared to traditional LCDs, OLEDs offer superior contrast ratios and wider viewing angles, leading to a more immersive user experience. The inherent thinness of OLED panels also contributes to the sleek design of many modern wearables.

The market offers various OLED display types suited for different wearable applications. These include rigid OLEDs for watches and fitness trackers, and flexible OLEDs for more advanced devices like smartwatches with curved screens. Choosing the right type depends on the design and functionality of your wearable product. Factors to consider include size, resolution, and power requirements.

A crucial factor when selecting a Best Wearable OLED factory is its production capacity. You need a manufacturer capable of meeting your order volume within your desired timeframe. Inquire about their production lines and their ability to handle both small and large-scale orders. Consider their history and proven track record of meeting deadlines.

Look for manufacturers with a strong understanding of OLED technology and a history of innovation. Consider their experience with different OLED types and their ability to adapt to emerging technologies. A factory investing in research and development is more likely to offer cutting-edge solutions and stay ahead of the competition. Review their patents and publications to gauge their technological capabilities.

Rigorous quality control is paramount in the manufacturing of OLED displays. A reliable Best Wearable OLED factory will have strict quality assurance processes in place, including regular testing and inspections. Look for certifications that demonstrate adherence to international quality standards, such as ISO 9001. Request samples to assess the quality of their products firsthand.

While cost is a critical consideration, avoid focusing solely on the lowest price. A transparent pricing structure that clearly outlines all fees and charges is essential. Compare quotes from multiple manufacturers to ensure you're getting a fair price for the quality and service offered. Consider factors like minimum order quantities (MOQs) and potential discounts for large orders.

Before you finalize your choice of Best Wearable OLED factory, create a detailed list of your requirements. This should encompass factors like display size, resolution, power consumption, brightness, color gamut, and desired lifespan. Collaborating with a reputable manufacturer will be key to transforming your design vision into a high-quality product. Don't hesitate to request references and conduct thorough due diligence.

While we cannot provide an exhaustive list here due to the constantly evolving nature of the industry, researching companies specializing in OLED display manufacturing and those with a proven track record in the wearable technology sector is advisable. Thoroughly vet potential partners before making a commitment.

Remember, selecting the right Best Wearable OLED factory is crucial for the success of your wearable project. By carefully considering the factors discussed above, you can ensure a smooth manufacturing process and a high-quality end product. For additional resources and to explore potential partnerships, consider visiting companies like Dalian Eastern Display Co., Ltd., a leader in display solutions.

| Feature | Importance |

|---|---|

| Production Capacity | High |

| Technology Expertise | High |

| Quality Control | High |

| Cost & Transparency | High |