This comprehensive guide explores the world of LCD glass, covering its types, properties, applications, and considerations for selection. Learn about different LCD glass technologies, their advantages and disadvantages, and how to choose the right one for your needs. We'll delve into the technical aspects, ensuring you have a clear understanding before making a purchase decision. This guide is perfect for anyone involved in the design, manufacturing, or purchasing of LCD displays.

The most common type, soda-lime LCD glass offers a good balance of cost-effectiveness and performance. It's widely used in many applications due to its relatively low price and acceptable optical properties. However, it's more susceptible to damage compared to other types. Its fragility needs to be considered when designing or handling devices using this LCD glass.

Offering enhanced strength and durability compared to soda-lime glass, aluminosilicate LCD glass is a popular choice for applications requiring increased robustness. It exhibits higher resistance to scratching and cracking. While more expensive than soda-lime, it’s preferred in applications where durability is paramount, such as industrial or outdoor displays. This increased durability often justifies the higher cost.

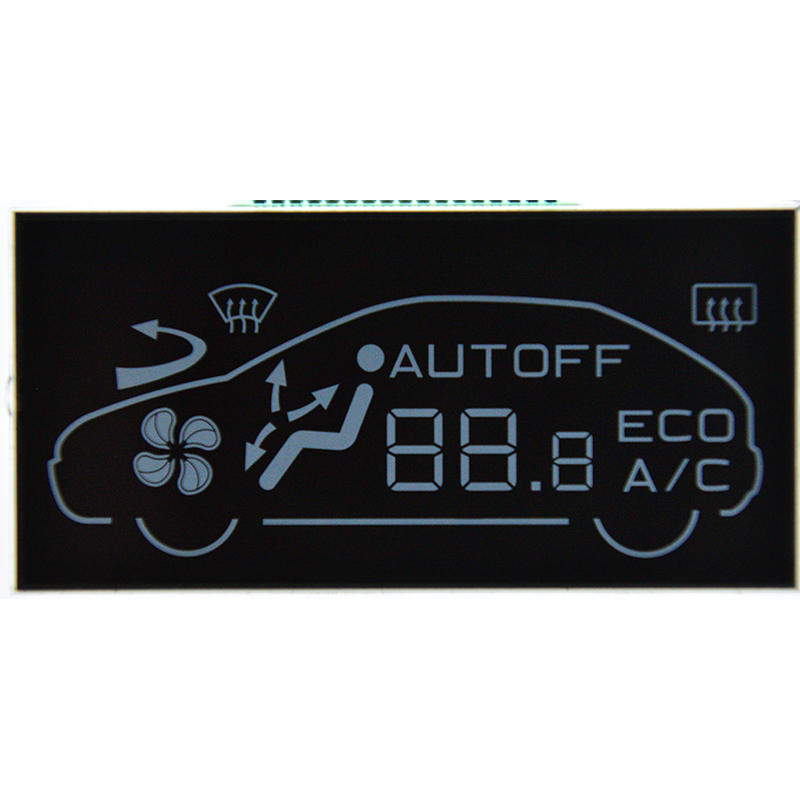

Known for its excellent thermal stability and low thermal expansion, Borofloat? LCD glass is ideal for applications with significant temperature fluctuations. Its superior performance in harsh environments makes it suitable for automotive displays, industrial panels, and other demanding applications. Its high cost is offset by its improved reliability and longevity. Learn more about Borofloat? glass.

Choosing the correct LCD glass involves considering several key properties:

| Property | Description | Importance |

|---|---|---|

| Thickness | Affects strength, weight, and cost. | Crucial for structural integrity and manufacturing process. |

| Surface Quality | Impacts image clarity and viewing experience. | Essential for optimal display performance. |

| Optical Properties | Includes transmittance, refractive index, and color. | Influences image quality and color accuracy. |

| Chemical Resistance | Determines durability in various environments. | Critical for long-term performance and lifespan. |

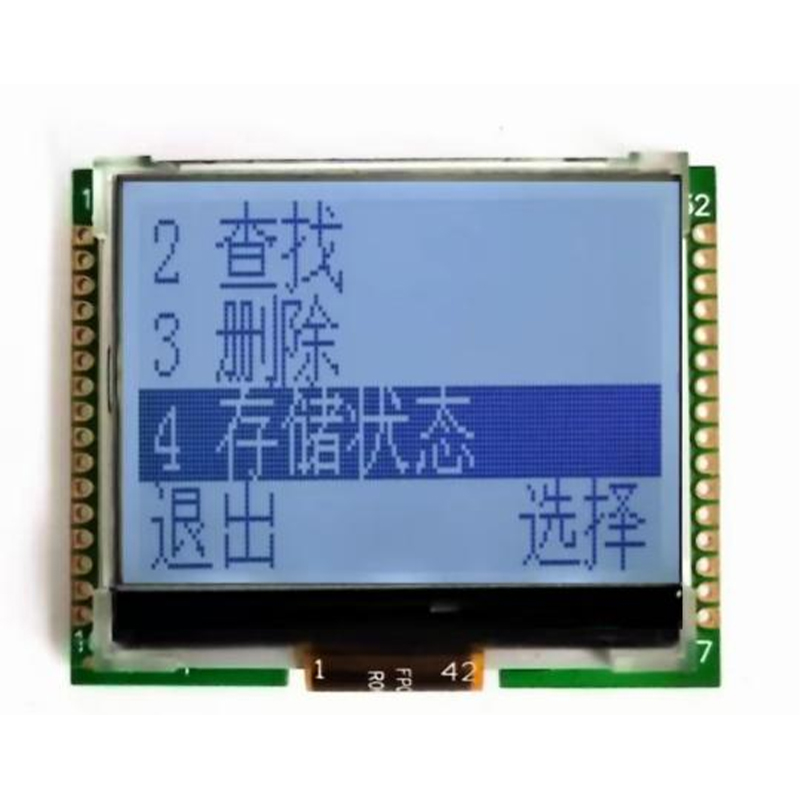

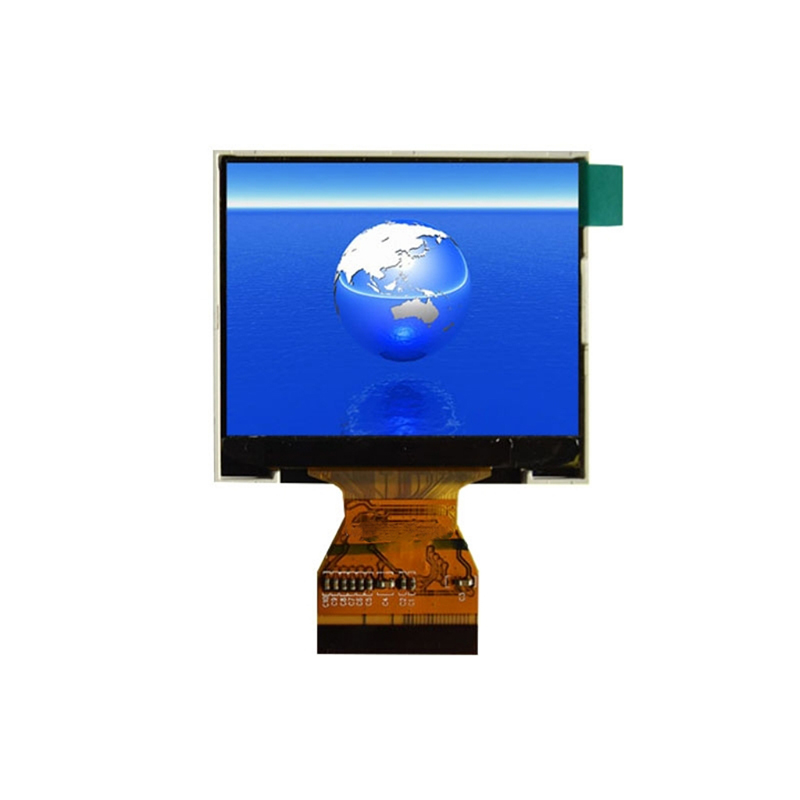

LCD glass finds widespread use across various industries:

The selection of appropriate LCD glass is highly dependent on the specific requirements of your application. Factors to consider include the desired lifespan, operating environment (temperature, humidity, etc.), the display size, cost constraints, and the desired optical quality. Consult with a specialist for complex applications or if you are unsure about which LCD glass type best suits your needs. For high-quality LCD glass solutions, consider exploring options from experienced manufacturers like Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/).

Understanding the various types and properties of LCD glass is crucial for successful product development and manufacturing. By carefully considering the factors discussed in this guide, you can select the optimal LCD glass for your specific application, ensuring optimal performance and longevity. Remember to consult with experts for complex projects and ensure your chosen supplier is reputable and delivers high-quality products.