Choosing the right LCD manufacturer is crucial for any project relying on high-quality liquid crystal displays. This comprehensive guide explores key factors to consider when selecting a manufacturer, helping you make an informed decision based on your specific requirements.

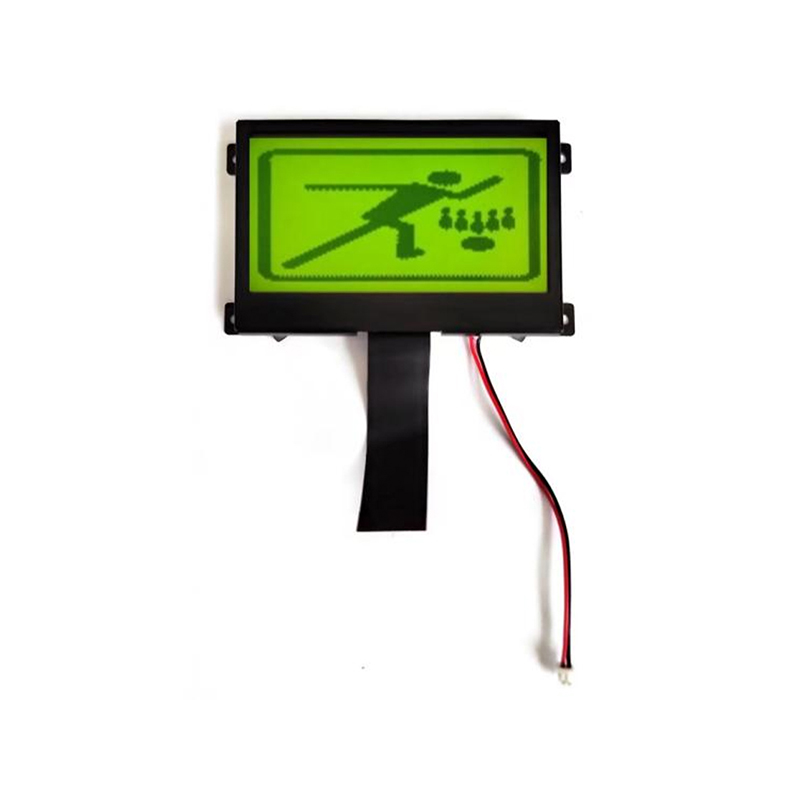

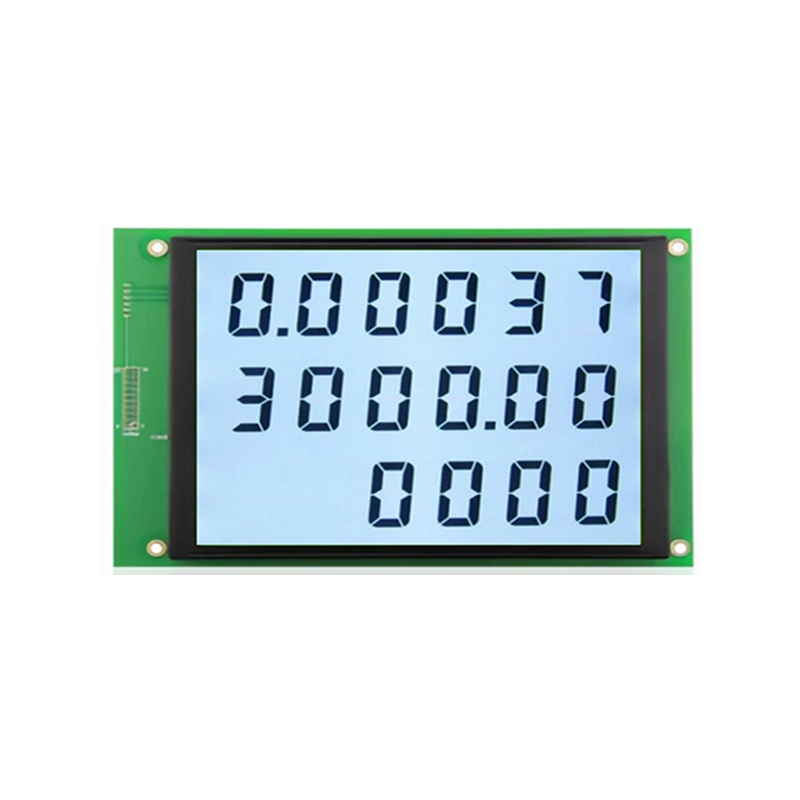

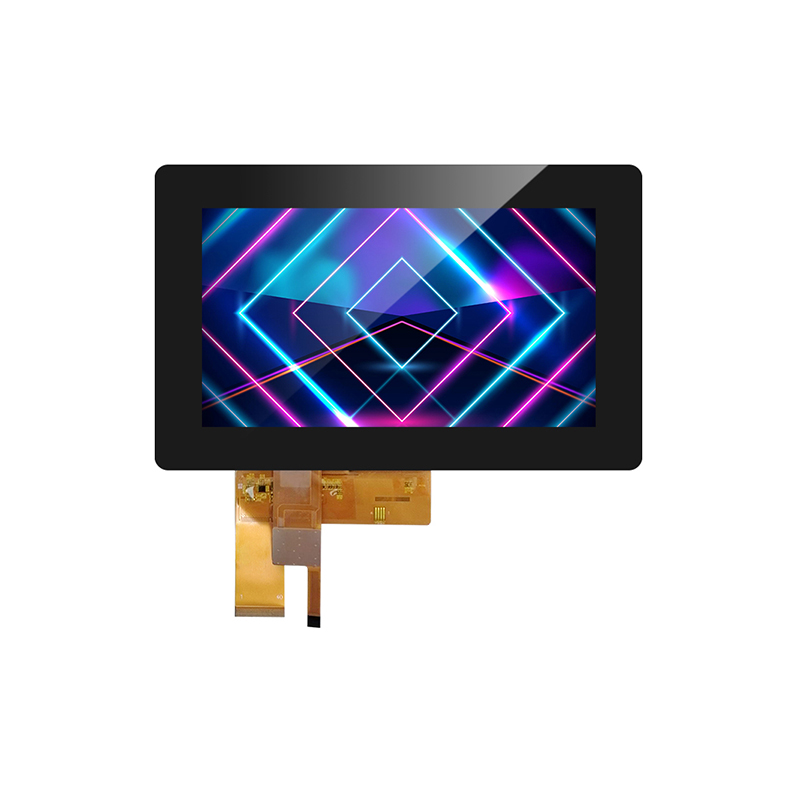

Before approaching any LCD manufacturer, clearly define your project's needs. Consider factors such as screen size, resolution, response time, brightness, contrast ratio, viewing angles, and operating temperature range. Are you looking for a standard LCD or a specialized display with unique features like touch functionality or high refresh rates? Knowing these specifications will help you narrow down your choices and communicate effectively with potential manufacturers.

The quantity of LCDs you require significantly impacts pricing and the suitability of different manufacturers. Large-volume orders often command lower per-unit costs, but may require longer lead times. Smaller-scale projects might benefit from manufacturers specializing in customized orders or offering smaller minimum order quantities (MOQs). Establish a realistic budget early in the process to guide your search.

The LCD manufacturing industry encompasses a wide range of companies, from large, multinational corporations to smaller, specialized firms. Some manufacturers focus on mass production, while others excel in custom design and development. Consider whether you need a standard product or a tailored solution when choosing a manufacturer. Researching different manufacturers' capabilities and focusing on those that align with your project's scale and specificity is crucial.

Look beyond just pricing. Investigate the manufacturer's experience, certifications (e.g., ISO 9001), and production capabilities. Review case studies and testimonials to gauge their quality and reliability. A reputable manufacturer will readily provide information on their production processes, quality control measures, and customer support services.

Geographic location impacts lead times, shipping costs, and communication ease. Consider the proximity of the manufacturer to your location or your distribution network. Understanding potential logistical challenges and associated costs is vital for effective project management.

| Factor | Importance | Considerations |

|---|---|---|

| Quality Control | High | Check certifications (ISO 9001), inquire about defect rates and return policies. |

| Lead Time | High | Understand production schedules and potential delays. Factor in shipping time. |

| Pricing and Payment Terms | High | Negotiate favorable terms and ensure transparency in pricing structures. |

| Customer Support | Medium | Assess responsiveness and willingness to address concerns. |

| Technology and Innovation | Medium | Consider the manufacturer’s commitment to R&D and new technologies. |

Table showing key factors to consider when selecting an LCD manufacturer.

Utilize online directories, industry publications, and trade shows to identify potential LCD manufacturers. Thoroughly vet each candidate by reviewing their website, contacting them directly, requesting samples, and checking references. Don't hesitate to ask detailed questions about their capabilities and processes.

For high-quality LCD solutions, consider exploring options like Dalian Eastern Display Co., Ltd., a reputable LCD manufacturer with extensive experience in the industry. Their commitment to quality and innovation makes them a strong contender for many projects.

Remember, selecting the right LCD manufacturer is a critical decision. By carefully considering the factors outlined in this guide, you can ensure a successful partnership and the delivery of high-quality displays for your project.