This guide provides a comprehensive overview of LVDS LCD testers, helping you select the ideal device for your specific requirements. We'll explore different types of testers, key features to consider, and factors to ensure compatibility with your LCD panels. Learn about essential functionalities, troubleshooting tips, and how to maximize your investment in a reliable LVDS LCD tester.

Low-Voltage Differential Signaling (LVDS) is a signaling standard used to transmit digital video data to LCD screens. It's known for its high speed, low power consumption, and excellent signal integrity, making it a popular choice for various applications, from small portable devices to large displays. Understanding the nuances of LVDS is crucial when selecting a suitable LVDS LCD tester.

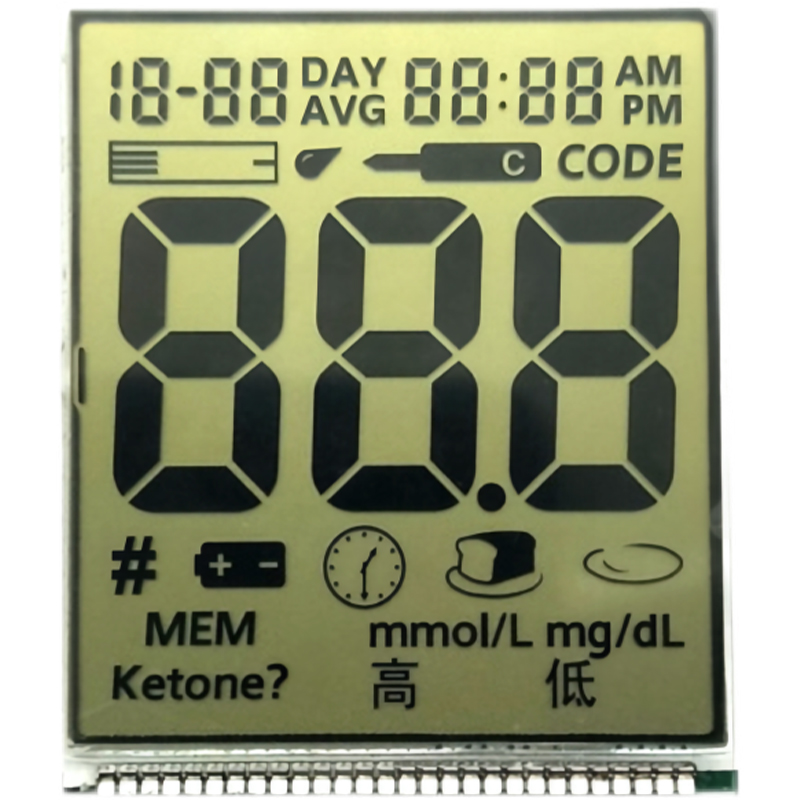

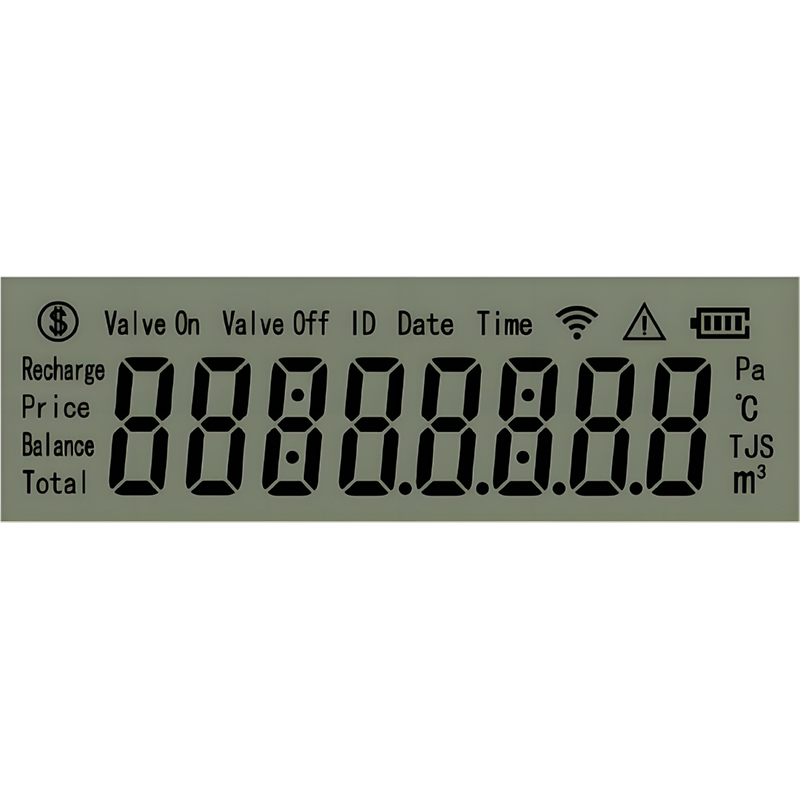

Testing is essential to ensure the quality and functionality of your LCD panels. A malfunctioning LCD can lead to significant losses, especially in manufacturing and repair environments. A robust LVDS LCD tester helps identify defects early, saving time and resources. Issues such as dead pixels, backlight problems, or signal transmission failures can be detected quickly and accurately.

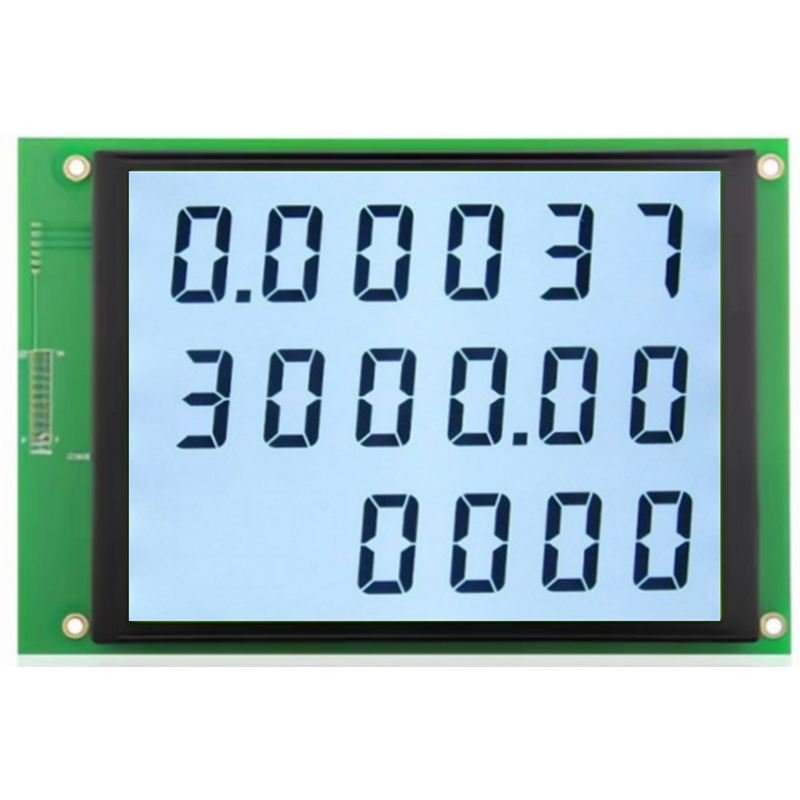

LVDS LCD testers come in various forms, each with specific capabilities and applications. The choice depends heavily on your budget, the complexity of your testing needs, and the type of LCD panels you're working with.

These are entry-level devices, often suitable for basic functionality checks. They might only test for power and backlight functionality, offering limited diagnostic capabilities. While cost-effective, they lack the advanced features of more sophisticated models.

Advanced testers provide comprehensive diagnostic capabilities, including the ability to analyze signal integrity, detect pixel defects, and perform more in-depth testing. These often offer programmable settings and support for various LCD panel resolutions and interfaces. They are ideal for professional applications.

For high-volume manufacturing or extensive testing needs, integrated systems offer automated testing capabilities, incorporating multiple test functions into a single unit. These solutions increase efficiency and reduce the time spent on individual testing.

Several factors need careful consideration when selecting a LVDS LCD tester. These features influence accuracy, ease of use, and overall effectiveness.

Ensure the tester supports the resolutions of your target LCD panels. Incompatibility can lead to inaccurate results or inability to test certain panels.

Confirm compatibility with the LVDS interface standard used by your LCD panels. Different LVDS variations exist, and incompatibility could render the tester unusable.

The tester should offer comprehensive diagnostic tools, allowing for detailed analysis of potential issues within the LCD panel.

A user-friendly interface simplifies the testing process and reduces the learning curve. Intuitive controls and clear displays are vital for efficient use.

The best LVDS LCD tester will depend on your specific needs. Consider the factors discussed above, along with your budget and the frequency of testing required. For assistance selecting a suitable tester for your application, consider contacting Dalian Eastern Display Co., Ltd. – a leading supplier of high-quality LCD components and testing equipment. They can provide expert guidance and product recommendations to meet your specific needs.

Here's a quick guide to troubleshooting common problems encountered during LVDS LCD testing:

| Problem | Possible Cause | Solution |

|---|---|---|

| No display | Power issue, cable problem, faulty LCD | Check power connections, inspect cables, replace LCD if necessary |

| Flickering display | Signal interference, loose connections, faulty LCD | Check connections, shield cables from interference, replace LCD if necessary |

| Pixel defects | Manufacturing defect, physical damage | Replace the LCD panel |

Remember to always consult the manufacturer's documentation for your specific LVDS LCD tester and LCD panel.

1 This information is based on general knowledge and experience in the field of LCD testing. Specific product details and functionalities may vary depending on the manufacturer and model.