SPI LCD: A Comprehensive GuideUnderstanding the nuances of SPI LCD technology is crucial for many embedded systems projects. This guide provides a deep dive into SPI LCDs, covering their functionality, advantages, disadvantages, and considerations for implementation. We'll explore different aspects of SPI LCD technology to help you choose the right display for your application.

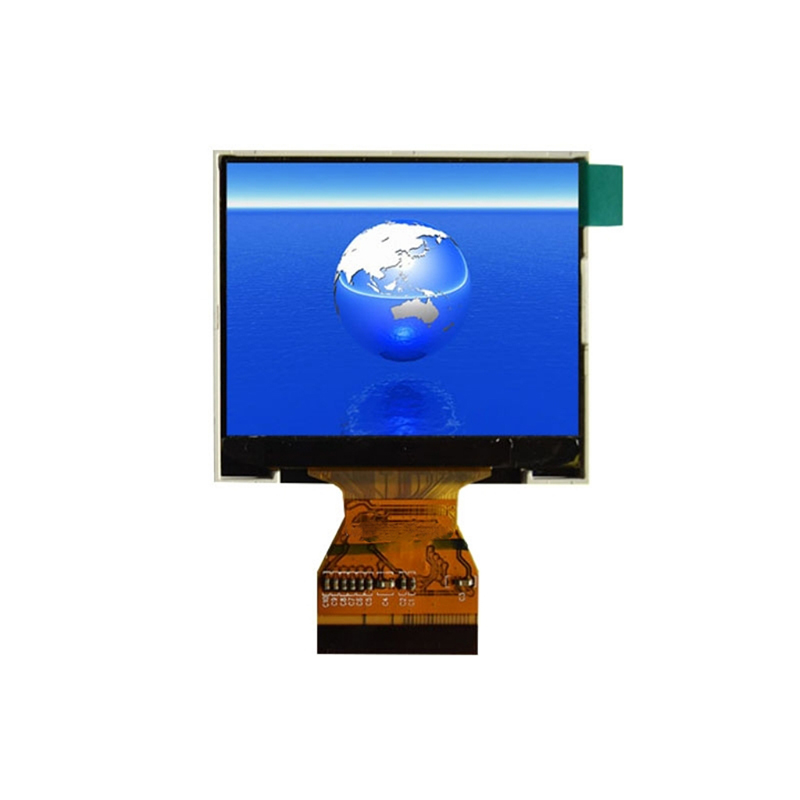

A SPI LCD (Serial Peripheral Interface Liquid Crystal Display) is a type of LCD that uses the Serial Peripheral Interface (SPI) protocol for communication. Unlike parallel interfaces, SPI requires fewer pins, making it a popular choice for space-constrained embedded systems. The SPI protocol offers flexibility and simplicity in controlling the SPI LCD, including data transfer, addressing pixels, and controlling various display settings. Choosing the right controller is vital for seamless integration into your project. Many microcontrollers readily support SPI, streamlining the setup process.

One significant advantage of SPI LCDs is their reduced pin count compared to parallel interfaces. This simplifies circuit design, reduces PCB space requirements, and can lead to cost savings. The fewer connections also minimize the risk of wiring errors and improve signal integrity.

SPI's master-slave architecture makes communication straightforward. The microcontroller (master) controls the data transmission to the SPI LCD (slave), simplifying the software implementation. This streamlined communication reduces development time and complexity.

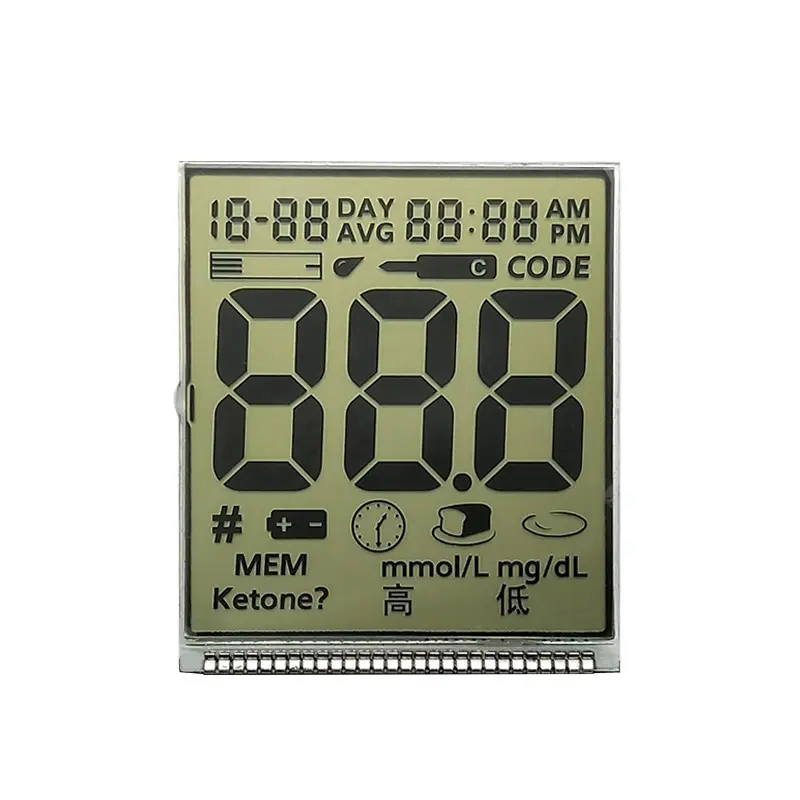

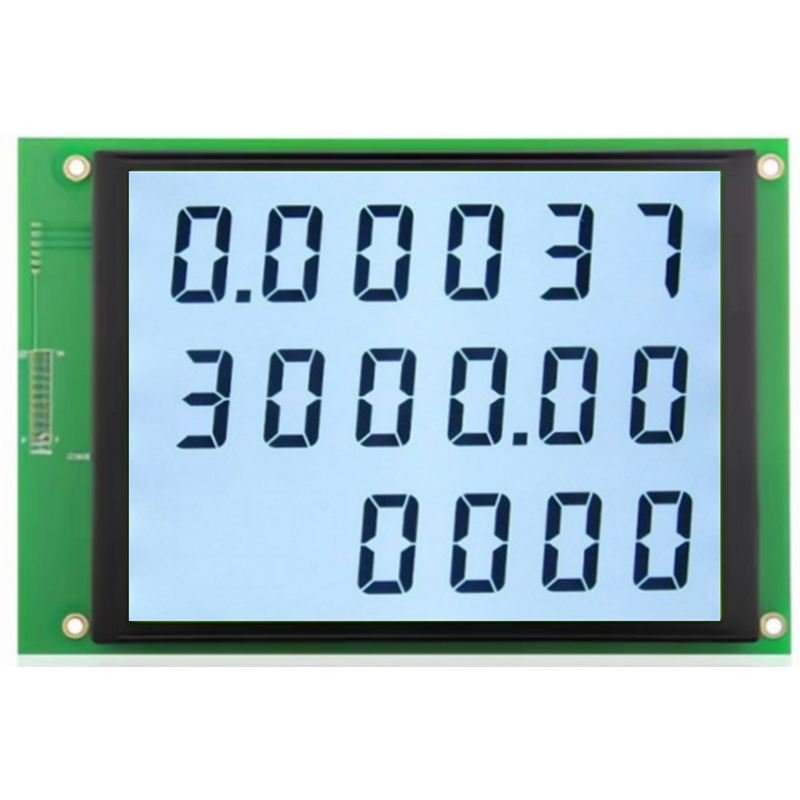

SPI's flexibility extends to various display sizes, resolutions, and functionalities. From small character LCDs to larger graphical displays, SPI technology provides adaptability across many applications. Consider the resolution, contrast, and backlight requirements when selecting an SPI LCD for your project.

In many instances, SPI LCDs offer a cost-effective solution, especially for projects where a low pin count and simple communication are prioritized. The ease of integration can further reduce the overall project cost.

Compared to parallel interfaces, SPI communication can be slower, particularly for high-resolution displays. The serial nature of data transfer can introduce limitations in frame rates and overall performance. This is a critical factor to consider when designing high-performance applications.

While suitable for various display sizes, managing the data transfer for high-resolution SPI LCDs can increase software complexity. Efficient data handling techniques and optimized drivers become essential for seamless performance.

Selecting the appropriate SPI LCD involves several factors. Consider the following:

Careful evaluation of these aspects will ensure optimal performance and seamless integration into your embedded system. Manufacturers like Dalian Eastern Display Co., Ltd. offer a wide range of SPI LCD options to cater to various project requirements.

Successful implementation requires careful attention to wiring, software configuration, and driver selection. Thorough testing and debugging are crucial for identifying and resolving any communication issues. Common problems include incorrect pin assignments, clock speed mismatches, and driver compatibility issues. Consult the datasheet of your chosen SPI LCD and microcontroller for detailed instructions and troubleshooting guidance. Remember to always check for proper voltage levels and grounding.

SPI LCDs offer a compelling solution for many embedded system applications, balancing simplicity, cost-effectiveness, and flexibility. By understanding their advantages, disadvantages, and implementation considerations, you can select and utilize them effectively to enhance your projects. The key is to meticulously plan your design and select the right display based on specific project requirements. Proper understanding and implementation will lead to a successful integration of SPI LCDs into your embedded systems.